How to insulate a balcony from the inside? Materials for thermal insulation: how not to make a mistake when choosing

What is the best way to insulate a balcony? Reviews from professionals do not give a clear answer. There are 5 popular thermal insulators: expanded clay, polystyrene foam, penofol, mineral wool and polystyrene foam. Each has advantages, disadvantages, and characteristics to consider.

Let's find out when to use each of these materials.

Styrofoam

To cover your balcony yourself inexpensively, choose a material that is easy to process. Polystyrene foam meets these requirements 100%.

Technologically, this material is a foamed and hardened plastic mass. Foam boards contain a lot of air, and air is an excellent thermal insulator.

It is used to insulate the outside of houses and sheathe rooms inside. This means it’s also suitable for a balcony.

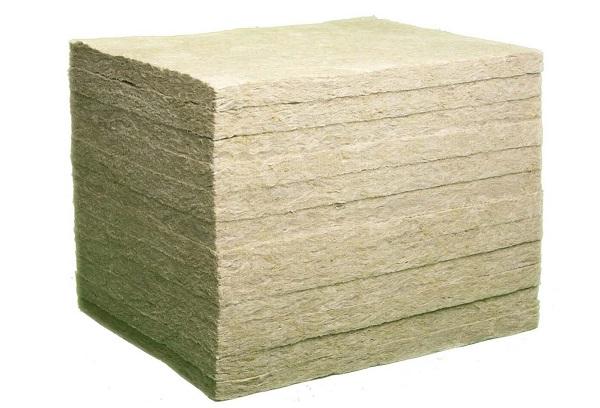

Mineral wool

It's not actually cotton wool. The material has nothing in common with cotton. Mineral wool is made from molten sand, dolomite, limestone, blast furnace slag or rocks.

Minerals are melted to a liquid state, the plastic mass is pulled into threads and a light porous material is formed from them.

Expanded clay

This thermal insulator is made from fusible clay or shale. In fact, this is ordinary ceramics, only granulated.

The clay is mixed with water, loaded into rotating drums and heated to 1300 OWITH.The material “boils” and pores appear in the granules, which provide expanded clay with high heat-insulating properties.

Penofol

This material is reminiscent of the fabric from which autumn jackets are sewn: a soft, porous mass can be felt under the smooth silver film.

The similarity is no coincidence. Penofol is made from polyethylene foam, which is covered with a thin layer of aluminum foil.

There are three types of material:

- A – covered with foil on one side;

- B – foil on both sides;

- C – foil on one side, self-adhesive on the other.

Penofol works like a thermos - the aluminum layer reflects heat, and the polyethylene foam serves as a thermal insulator. A thin layer of this material is as effective as thicker foam or mineral wool.

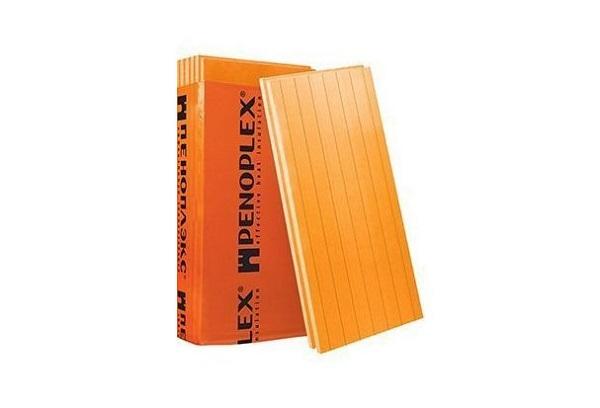

Penoplex

This material is the “brother” of foam plastic. Penoplex is made from the same raw materials, but using a different technology.

Granular foam is placed in a special extruded unit, heated and catalytic gases are added. During processing, the material foams, swells and turns into a voluminous porous mass. The diameter of one penoplex cell is from 0.1 to 0.3 mm, and each cell is isolated from the others.

When the foam mass cools, it becomes strong - much stronger than polystyrene foam. The shapeless blanks are cut into rectangles, and the familiar dense orange slabs are obtained.

comparison table

For clarity, let's collect all the characteristics in a table.

| Characteristic | Styrofoam | Mineral wool | Expanded clay | Penofol | Penoplex |

| Ease of installation

|

+ | — | — | + | + |

| Environmental friendliness | — | + | + | — | — |

| Fire safety | — | + | + | + | — |

| Thermal insulation quality | — | — | — | + | + |

| Durability | — | + | + | + | — |

| Soundproofing | — | + | — | — | + |

| Vapor permeability | — | + | + | — | — |

| Price (economy option) | From 40 rub. for 1 m2. | From 180 rub. per sheet 60 by 80 cm. | From 30 rub. for 20 liters. | From 70 rub. for 0.6 m2 (self-adhesive). | From 113 rubles per sheet 118.5 by 58.5 cm. |

Foam plastic has the most cons - but it is the cheapest. And most of all the advantages of the most ordinary mineral wool.

What are the differences between different types of thermal insulators?

Insulation materials are divided into:

- in form: durable sheets, rolls, bulk materials, foaming agents;

- by fastening method: materials are poured, glued, secured with dowels or nails, placed inside the structure, on the outside or on the inside;

- by chemical composition: plastics, minerals, clay.

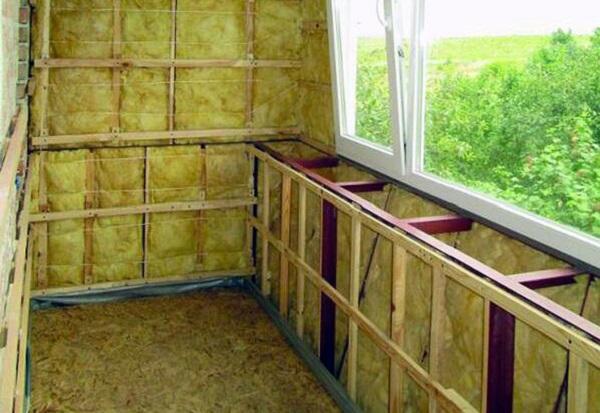

Sheets are conveniently attached to vertical surfaces. Soft thermal insulators, packaged in rolls, perfectly fill niches in frames. They can be laid very tightly - so that there are no cold bridges left. Bulk materials are universal. You can fill the vertical frame, or you can add it to concrete as a filler and pour the floor.

Foam penetrates into the most inaccessible areas, completely fills niches, leaving no gaps.

The strength, durability and safety of materials depend on the chemical composition.

Foam plastic: pros and cons

Polystyrene foam is one of the most popular thermal insulators.

Advantages

This versatile material has many advantages.

- Polystyrene foam is convenient to transport and store.

The material is sold in blocks of large squares. You take such a block, easily lift it in an elevator or up the stairs and place it in an empty place. All.

- Easy to handle.

You can cut foam plastic even with an ordinary kitchen knife if you sharpen it well.

- Convenient to install.

Foam boards are attached with glue or with special plastic dowels with wide caps. You don't need special tools or professional skills.

- Polystyrene foam is not afraid of water and temperature changes.

It does not absorb moisture, does not rot or crumble. If you treat the stove with special compounds, fungus and mold will not appear there.

- Low cost.

This is the most affordable of insulation materials. Only 40 rubles per 1 m2.

Flaws

This material also has disadvantages.

- Styrofoam is flammable.

Many people think that this material does not burn. Not true. It burns, and in the process emits thick clouds of toxic black smoke. If you often smoke on the balcony, choose a different insulation.

- Styrofoam harbors rodents.

Mice make burrows in foam plastic boards and breed there. If you live on the ground floor, rodents will be a serious problem.

- When heated, it releases toxic substances.

If you combine a balcony with a living space, do not hang a powerful heater or radiator on a foam-insulated wall.

- Polystyrene foam is fragile.

The material crumbles and breaks even under slight pressure. If you plan to insulate the floor, you will have to make a frame.

- Over time, an unpleasant odor appears.

For a balcony, this problem is solved by opening the windows slightly for ventilation. But if you are going to connect the room to a living room, use a different thermal insulator.

Mineral wool: pros and cons

This thermal insulator is a champion in terms of the ratio of advantages and disadvantages..

Advantages

Builders have many reasons to use mineral wool for insulation.

- Wide range of material types.

Mineral wool is sold in rolls, in mats, in slabs and in bulk; it can be thick and thin, hard, soft and blown. You can choose the option that best suits your goals.

- Minvata is breathing.

If you want to cover an insulated balcony with wood, it is important to ensure natural air circulation.

- The material does not rot, does not burn, and when heated, does not release toxins.

Fire barriers are made from mineral wool. This material does not ignite even at temperatures of 1000 O.

- No phenols.

Some people think that mineral wool releases toxic substances. 70 years ago this was true, but now technology has changed. Now mineral wool contains a minimum of phenol-containing substances, and they do not evaporate.

Good sound insulator.

Excellent at cutting out aggressive street noise.

Flaws

Mineral wool has two significant disadvantages.

- Absorbs moisture.

And water conducts heat well. Moisten mineral wool by 2% and it will lose 15% of its effectiveness as a thermal insulator. Balconies insulated with this material must be properly vapor and waterproofed.

- Collects dust.

If you do not properly insulate the mineral wool and combine the balcony with the room, problems may arise. Especially if there are allergy sufferers in the family.

Glass wool is potentially dangerous. Fine, brittle fibers get stuck in clothing, dig into the skin, and cause lung irritation when breathing. This is why professionals prefer insulators made from stone or slag.

Expanded clay: pros and cons

This material has many strengths, but also weaknesses.

Advantages

Expanded clay is pieces of ceramics, and that says it all.

- Does not ignite.

Ceramics do not burn.

- Long lasting.

The insulation will last from 40 to 60 years.

- Not afraid of either heat or cold.

Expanded clay does not crack, does not deform and can withstand up to 300 freezes.

- Can be used for floor insulation.

Pebbles are simply added to concrete as a filler, but they can also be poured under boards.

- Eco-friendly material.

It's just baked clay.It contains foreign chemicals, toxins or heavy metals.

- Biological resistance.

Mold and mildew do not grow on expanded clay, and rodents do not live in this material.

Flaws

Expanded clay has three significant disadvantages.

- The thermal insulation layer must be thick.

At least 20 cm - and this is only expanded clay. And also the frame, cladding... You will lose a lot of usable space.

- Ceramics absorbs moisture well.

1 kg of expanded clay can absorb 200 ml of water. This reduces the thermal insulation properties and increases the humidity in the room.

- It is inconvenient to insulate walls.

Expanded clay is loose, which means you need to make a strong, fine-mesh vertical frame for it. But there are no problems with floor insulation and flow.

Penofol: pros and cons

Why do craftsmen love this material, and what problems do they face?

Advantages

This is the most convenient heat insulator to use.

- Penofol is glued like ordinary wallpaper, only the paste does not need to be diluted.

You simply buy a roll and cover the walls from the inside; the material is attached with a simple press. For reliability, the edges are fixed to the surface with a stapler.

- The material takes up little space.

Up to 0.5 cm maximum - ideal for insulating a small balcony.

- You don't have to clean up trash after work.

Penofol does not break or crumble, and dust does not fall off it.

- Not afraid of moisture.

The material is steam and waterproof, it does not grow mold and fungi.

- Fireproof.

Metal foil does not burn.

Flaws

Penofol has minor disadvantages.

- Aluminum conducts current.

- Take care of high-quality insulation of the wiring.

The material is soft, it can be pressed even with the pressure of a finger. You will not be able to paste wallpaper or apply plaster on penofol. Typically, penofol is sheathed with plasterboard, wood or plastic.

Penoplex: pros and cons

Craftsmen appreciate the high thermal insulation properties of penoplex, but there are also plenty of problems with the material.

Advantages

Penoplex is an improved foam plastic.

- Effective thermal insulator.

2 cm of penoplex has the same insulating properties as 3 cm of polystyrene foam or 4 cm of mineral wool.

- Durable – for porous materials.

Penoplex is one of the most durable thermal insulators. You can lean on it and put pressure on it - the material will withstand everything except a direct strong blow.

- Easy to install.

You can insulate your balcony with your own hands.

- Vapor-proof.

The material provides excellent waterproofing.

- Favorable price-quality ratio.

Penoplex is more expensive than polystyrene foam, but better quality and more practical.

Flaws

Penoplex has few disadvantages, but they are serious.

- Damage hazard.

Penoplex can be set on fire with a regular match. When burned, this material smokes heavily and releases dangerous toxins into the air: carbon monoxide, phosgene, cyano and hydrogen bromide. There are fire-resistant types of penoplex, but they are more expensive. In addition, when exposed to strong heat, they also release toxins.

- Vapor tightness.

This is an advantage - but it is also a disadvantage. Moisture that does seep into the structure does not evaporate completely. As a result, the material located under the penoplex becomes damp and collapses. The combination of penoplex with wood is especially destructive - the boards rot, mold and fungi grow in them. Fragility.

Manufacturers claim that the service life of penoplex is about 50 years. But the masters say: the material begins to deteriorate after 15-20 years.

What to choose?

Experienced professionals advise paying attention to such moments.

- What are you planning to cover the walls with?

If you want to cover an insulated balcony with clapboard, do not use penoplex. Take mineral wool, it will provide natural ventilation.

- Do you want to save usable space?

So your option is penofol. This is the thinnest thermal insulator.

- Are there any family members with allergies?

Polystyrene foam, expanded clay and penofol are hypoallergenic and are guaranteed not to emit toxins.

- Do you live above a noisy highway or is there music constantly playing underneath your house?

This means you need good sound insulation. Use mineral wool or penoplex.

- Do you have experience in construction work?

If you are starting self-repair for the first time, use penoplex, penofol or polystyrene foam. Mineral wool is too soft and more difficult to install. And the most problematic material for vertical thermal insulation is expanded clay.

- Do you want to save money?

Then take polystyrene foam. This is the most economical option. Otherwise, buy penoplex, mineral wool or penofol.

As you can see, there is no universal answer. Materials are selected depending on the situation. Clearly define your goals, write down on a piece of paper a list of problems that you want to solve - and you will understand how to insulate your balcony.