How to sharpen drills correctly - 3 easy ways

Content:

With constant use, drills last 2–3 weeks. Considering that many of them are expensive, and it is not easy to find a good sharpening specialist, many try to restore them themselves. How to sharpen drills? There are many different sharpening methods. We will talk about the simplest ones, which do not require expensive electrical equipment.

3 main rules

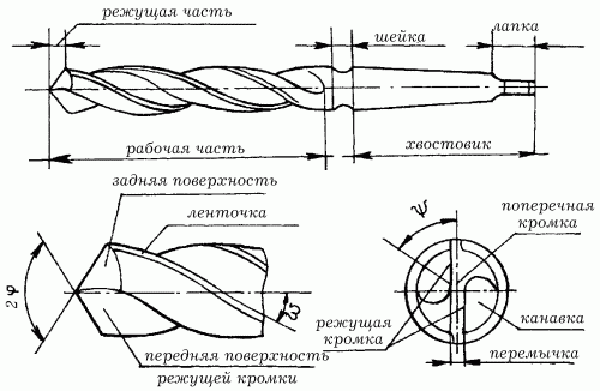

Before starting work, you should familiarize yourself with the structure of the drill. The tool consists of a shank and a working part, at the end of which there are elements involved in cutting metal or other material:

- two cutting edges

- rear surfaces (platforms behind the cutting edges),

- jumper.

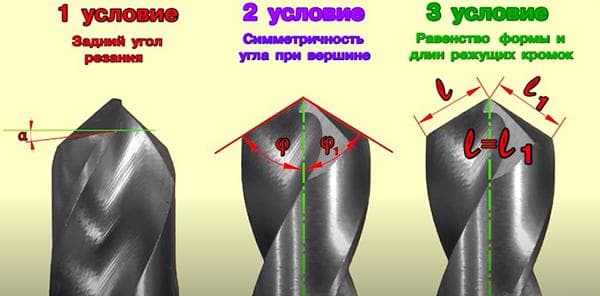

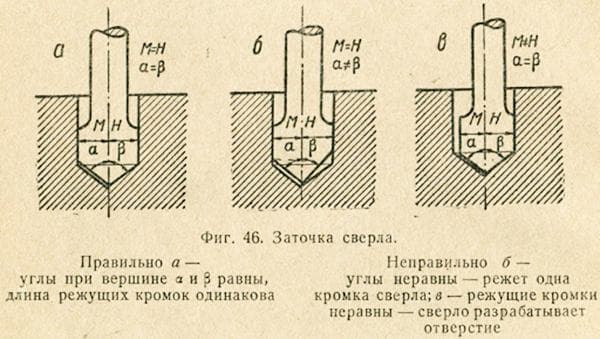

The sharpened drill looks like this:

- The two cutting edges are sharp and symmetrical to each other.

- The flanks are beveled and positioned below the cutting edge. That is, there is a gap between the part to be drilled and the tip of the tool.

- The bridge is not too thick and is located in the center.

In order to sharpen drills efficiently, it is important to arrange good lighting in the room. A person must have good eyesight. If your vision is poor or the instrument is small, you will need a magnifying glass (glasses with magnification).

Stages of work

According to the rules, sharpening should be done in a utility room, in a garage or, in extreme cases, on a balcony. Under no circumstances should you perform work in the kitchen. Metal shavings and dust will fly around the workplace. It must not get into the eyes, digestive organs, or respiratory tract. You should wear glasses, and after finishing sharpening, vacuum the room and do wet cleaning.

Sharpening a drill consists of several stages:

- Preparing the sharpening tool.

- Determining the exact angle and method of sharpening.

- Sharpening. First, the back surface of the drill is ground off, then the cutting edge is straightened and the jumper is reduced (if necessary).

- Finishing until smooth.

- Cleaning.

When sharpening, you must ensure that the drill does not overheat. Otherwise, the risk of deformation increases. Place a container with machine oil (or, in extreme cases, water) nearby. After drilling each point, lower the drill bit into the liquid for 2-3 minutes.

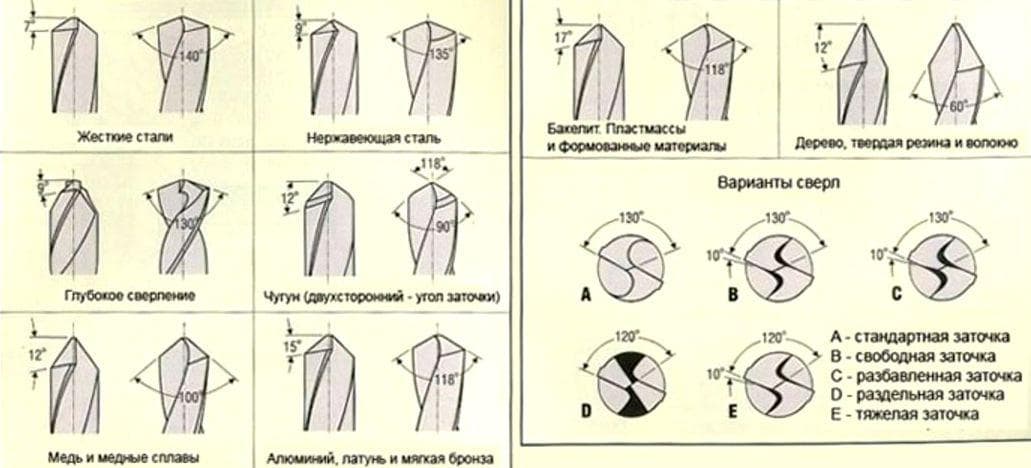

Defining Angle and Shape

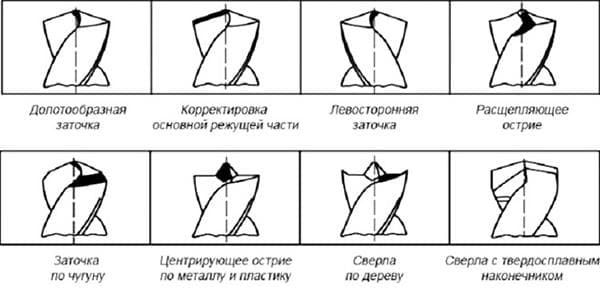

The main task when sharpening a drill is to restore the factory shape. Drills can be flat, spiral, center, with one or more edges. Some are designed for wood, others for plastic, metal, copper, etc. According to the purpose of the cutting part, the correct shape is given.

The most popular is the twist drill for metal. It is used for drilling wood, metal of medium and low hardness, and plastic. When sharpening such a tool, maintain a vertex angle of 118 degrees (if necessary, it can be changed by 30% up or down). The front angle is 20 degrees, the rear angle is 10 degrees.

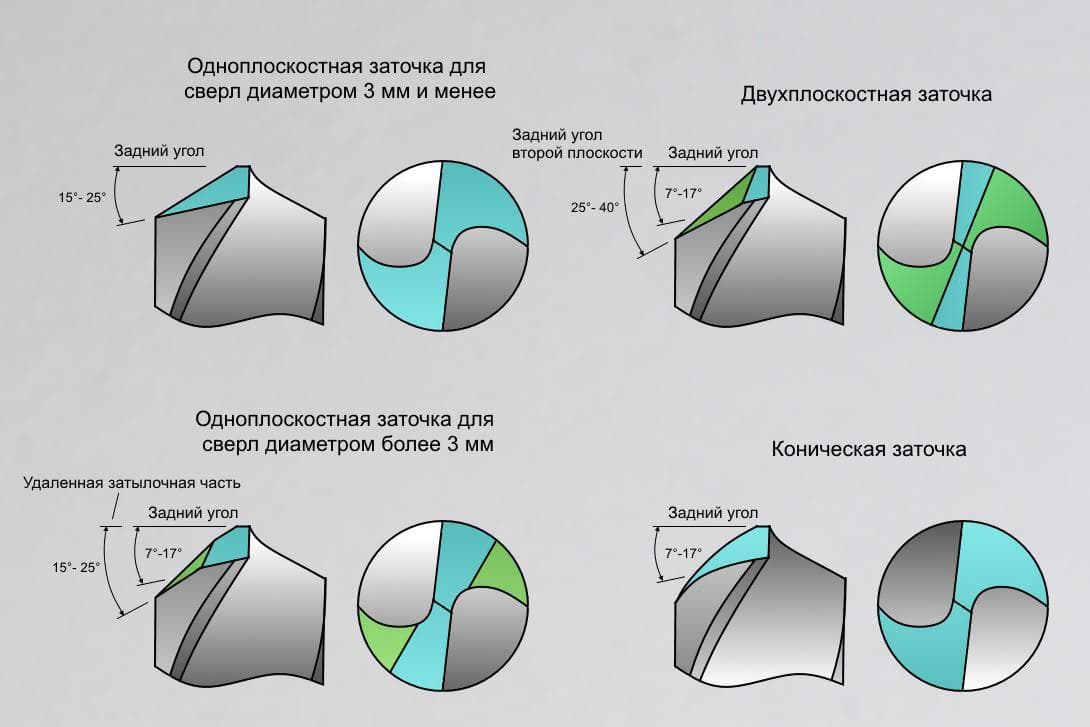

Conical and single-plane sharpening

These are the two most common ways to form a back corner at an apex.

- A conical clearance angle is formed for drills of large diameter - from 3 mm and above. To do this, the product is held with both hands, pressed against a grindstone on sandpaper and smoothly rocked with equal pressure. Two teeth are sharpened in a similar way.

- Single plane clearance angle suitable for small drills 1-3mm in diameter. The teeth are ground in one plane parallel to the sandpaper. In this case, the tilt can be 28–30 degrees.

Sharpening methods

Carpentry shops use sharpening machines for drills. Professional equipment is precise and allows you to quickly restore cutting ability. However, the cost of good machines is quite high - 90–200 thousand rubles.

At home, instead of sharpening machines, use a grinder, emery cloth, or a special attachment for a drill. All three methods are relatively easy and allow you to sharpen twist drills in a few minutes.

Experienced craftsmen are able to maintain the desired sharpening angle “by eye”. It is difficult for beginners to do this - they are recommended to make a special device from scrap items. For example, from a suitable size bolt, nut and powerful magnet, metal corners, wooden block:

At a minimum, you should mark a line on the sanding tool (or, in extreme cases, the table) at the desired angle. Use a protractor.

Sharpening on a grinding wheel

An emery machine equipped with a grinding wheel is a universal device. If available, sharpening the drill bits will take a few minutes.

What do we have to do:

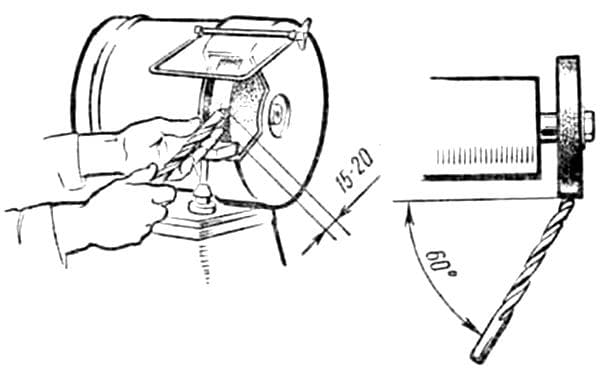

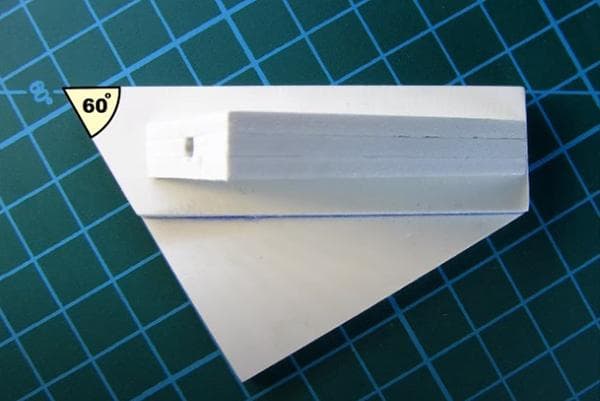

- Position the drill at an angle of 60 degrees relative to the plane of the grinding wheel. The cutting edge should take a horizontal position and be parallel to the circle.

- If the drill is large, severely damaged, or worn out, you should first use a rough metal sharpener, and then a soft one. In other cases, you can use only one wheel - for fine sharpening.

- Place your left hand with the tool on the rest. Secure the drill with your thumb. With your right hand, grab the shank.

- Turn on the sander. Carefully move the drill. Press the cutting edge against the surface of the wheel and smoothly move the tip up, lowering the shank. When performing sliding movements, maintain a 60-degree angle and do not release pressure.

- Rotate the drill 180 degrees. Position it in the same way (see step 1) and sharpen it (step 4). The main task is to make the back surfaces smooth and with the same slope.

- Continue sharpening the tool evenly on both sides until the cutting edges are sharp.

- Check if the edges are symmetrical. If necessary, adjust their length.

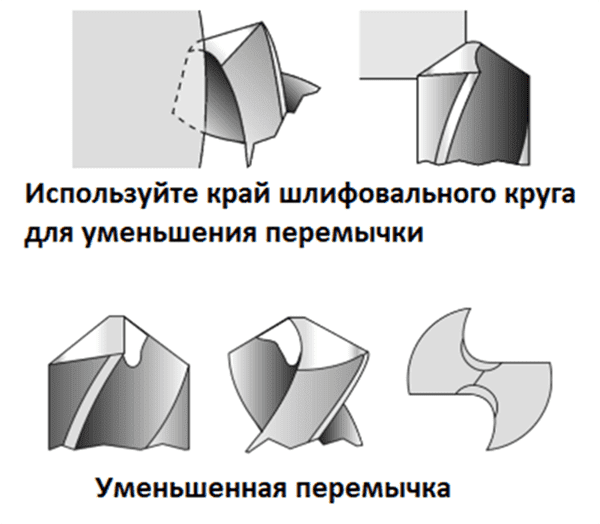

- Reduce the jumper if it is too wide. This will help reduce resistance when cutting metal.

The speed of rotation of the grinding wheel depends on the hardness of the material. The harder the drill, the slower it should rotate.

Sharpening on an angle grinder

A grinder should be used only in extreme cases. Being mobile, it can cause injuries. To avoid unpleasant situations, it is recommended to securely fasten the tool to a sheet of plywood or insert it into a vice. Hobbyists also make special devices for guiding and holding drills at a certain angle. They are attached to the grinder. The result is a convenient and efficient sharpening machine.

For sharpening, an abrasive wheel is installed on the grinder. The further course of work is exactly the same as when using a sharpening machine:

- The drill is installed at the desired angle to the abrasive disc.

- The back surface of one tooth is ground down, then the second.

- The length of the cutting edges is adjusted.

- The jumper is sharpened.

A grinder can only sharpen thin drills. When sharpening a hard tool with a large diameter, there is a high risk of injury.

Using a drill attachment

Craftsmen who want to make their job of sharpening drills easier use a special drill attachment. The device looks like a cartridge. Inside there is a specially shaped sanding stone with a preset angle of 118 degrees. Also on the nozzle there are 15 holes for twist drills of different diameters (3.5–10 mm). When turned on, the stone rotates and sharpens the tool. The average cost of a nozzle is 800 rubles. (SPARTA 912305).

For sharpening you need:

- Install the attachment on the drill.

- Insert the drill into the hole of the nozzle of the appropriate diameter until it stops.

- Turn on the electric drill for 20–30 seconds.

Despite the obvious advantages of the nozzle - simplicity and ease of use - the method has disadvantages:

- With the help of the device, you can sharpen only slightly dull instruments without serious damage.

- The attachment can be attached to a drill with a neck diameter of 43 mm, and sharpening can be done at only one angle - 118 degrees. The attachment is not suitable for drills for wood and non-ferrous metals.

How to sharpen small drills?

Thin drills with a diameter of 1–3 mm quickly become dull and sometimes even break completely. It will be difficult for a beginner to sharpen them with sandpaper: the cutting parts are too small and grind down even with slight pressure. There is a risk of deforming the instrument.

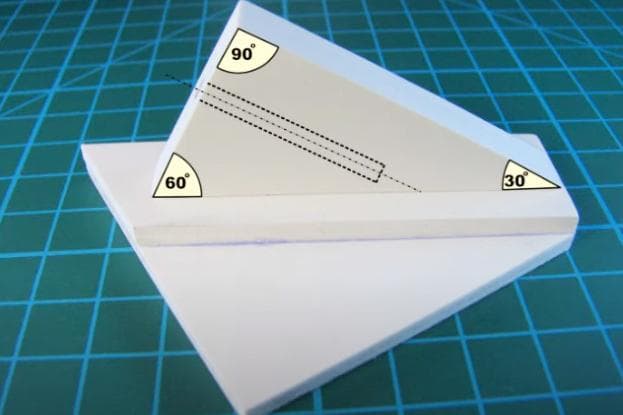

It is better to use a whetstone or a diamond file. You will also need a device that allows you to maintain the desired sharpening angle.Cut it out of PVC or wood, maintaining angles of 90, 60, 30 degrees.

The shank should turn in it, but not dangle.

How to sharpen correctly:

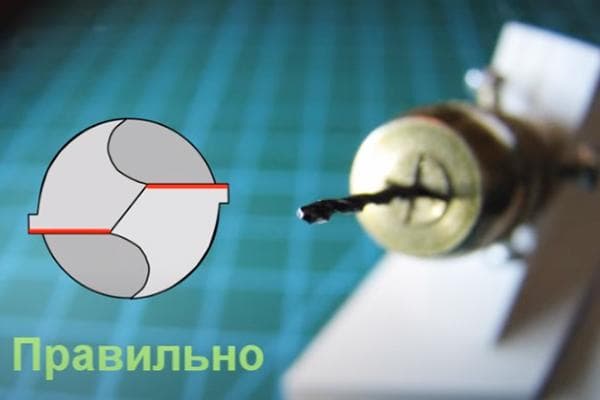

- Install the drill as shown in the image.

- Place the whetstone and move the drill with slight pressure.

- Do about 10 movements.

- Rotate the drill 180 degrees and repeat the manipulation.

- Evaluate the quality of sharpening using a magnifying glass.

- Continue sharpening the drill until you achieve the desired result.

Questions and answers

Is it possible to sharpen drill bits using sandpaper?

Yes. But manual sharpening will take several hours. To speed up the process, the paper or the drill itself is attached to a rotating element that makes 1000 revolutions per minute (screwdriver, electric drill). You can fix the drill in the chuck of an electric drill, turn on reverse (reverse) and drill several holes in the sandpaper. Sharpening on the reverse will “revive” the instrument a little.

Which drills cannot be sharpened at home?

High density and hard. For example, used for cutting cast iron.

How do you know if a tool needs sharpening?

The first sign that it’s time to sharpen the drill is a creaking sound at the beginning of drilling. At the same time, the tool will become very hot and wear out quickly.

The ability to sharpen drills is an indicator of the qualifications of specialists in technical professions. This is a rather complex process consisting of many nuances. It is impossible to describe all the subtleties in one article. The above methods will help you master the basics. What follows is a matter of practice. Any skill develops over a certain period of time. If your first attempt is unsuccessful, don't give up. Reread the material again, check the sharpening angles and proportionality.Correct any mistakes made. A little patience - and the task will be solved.

Always by eye. But the material is impressive

Damn, the easiest way to drill a nut from the edge side and sharpen it according to this template, without any problems

Another supporter of morons with nuts!?

Yes, but to drill the nut, you need to sharpen the drill..((

Test material. NraiTtsa. Previously, I also sharpened drills “by eye,” but it turned out rather crooked. I made a device for sharpening drills. Here, by the way, this device is indicated in this article. Now I don't suffer.

It depends on the eye. I always sharpen them by eye and see no difference when drilling with a new and a sharpened drill.

I paid 35 rubles, 25 pieces were sharpened and I’ve been using them for a year.

Previously, this was a whole industry and the Sharpener’s profession was always valued. Now this is a rarity.There are few production facilities, and office plankton are not trained in this matter. Is it easier to play tanks?

the easiest option!

35 rubles for sharpening 25 drills!? buddy, have you messed up anything? I’ll still believe 350 rubles, and even then it won’t be enough, let’s say I wouldn’t even go near the sandpaper for 350 rubles!!

Turner with 30 years of experience. But I still found a couple of tricks in the article that I didn’t know.

Such nonsense, it’s easier to buy a new drill for 50 rubles. They have created a whole science, more serious than the space industry...

And the store is closed!

Vasya, you are so Vasya... Think about it, bread and sausage don’t grow on trees... )))

Eh Vasya, Vasya……..

Vasya, you're right, if you need one hole per year, 50 rubles is not money, but if it's 300 a day, then Vasya, science will help you

Eh Vasya Vasya….. With such an attitude, soon the Chinese will sharpen drills for you.

you're a handyman, you have nothing to do, you don't know how, you don't want to learn, you write nonsense, when you have 100 drills, they sat down, you'll go buy

You Vasya are a hand-assed office plankton!!!

That's right!))) live one day at a time, why rack your brains, it will never be useful)…

Vasya, don’t you wash your socks, but always buy new ones?

Vasya is smart, Vasya is rich.

50 rubles small drill. Serious drills and they cost seriously. Moreover, if there are several dozen of them and you drill often. It’s not just buying, you’ll go broke on the sharpener. It’s better to read smart recommendations and train your hands. Money saved is money earned.

That's right, only if you use the drill once every few years. What if it’s constant? You’ll go broke on drills. But this science has long been discredited. How do you think about training people in a specialty?

Vasya, what if the drill is 30? or let it be 6, but you need a lot of them, let’s say 100 pieces, and the drills in most cases are shitty, after three holes you need to sharpen, although if the chickens don’t bite for money.....

It’s not easier, store-bought sharpening doesn’t suit me at all, it doesn’t remove much per turn and gets very hot, and also gets dull quickly. with normal sharpening, a hand drill drills faster than a kilowatt electric drill with a poor shop drill.

Shown drawings and posters for students of vocational education to train specialists in metal processing. For the average person, he will sharpen the drill several times and find the moment that the drill will drill, trial and error, the sharpening angle is different for different metals.

trial and error method, of course, higher school, for example, about my grandmother, I didn’t know how to read, but my grandmother looked at the pictures, they taught me to read at 25, but they sent me to school and at the age of 7 they forced me to read, so you can make mistakes ad infinitum, or even sharpen them at the age of 7

didn’t drink, didn’t smoke, was sent to school at age 7, and away we go

Not any trial and error. Well written and understandable. Get into it and use it.

Son, what did you forget on the women's forum??? The collective farm here is only your opinion, hand over the phone to your mother and sleep well

I sharpen drills at work with a grinder because the emery broke; I drill iron and aluminum) the main thing is not to burn it! and there's a whole problem here

The sharpening angle depends on the material that we will drill. Or rather, not only from him, but also from his hardness. Angle (also a back angle), which creates the so-called cutting edge. ribbon.finally…. jumper, This is how the masters taught me....Then I studied to become a master myself.

This is an “easy way” for a MASTER, and not for any person.I am not a botanist, I was a 4th grade milling operator in the past, but I give my drills specifically to MASTERS for resharpening.

)

I worked all my life, with my hands, I also sharpened drills, only with emery, there is a special stone for this, no problem, I can sharpen the drill even on a grinder, but with complex metals, where there is double sharpening of the jumper, only a diamond wheel

They showed it once and sharpened it the first time, but here you can write a dissertation like an instruction manual for a tablespoon.

There are textbooks. It's a must read, but the authors are great. Not everyone can share their knowledge. And it's never too late to learn.

Absolutely correct!

Author, thank you for the useful article. I put it in Favorist.

the current fool knows everything and... Vasya is a handyman

Golden words. I worked at a factory as a sharpener of metal-cutting tools. Until you get good at it, time passes. Well, the mentors were good.

Buying a new drill every time is expensive. Good article.

Test and voluminous material. This is needed for factory practice for beginners. Well done.

The smart one will read it and use it, but the fool is a handyman

will only discuss, there is no mind to do it.

...a twist drill has 5 edges: 2 main, 2 (side spiral) auxiliary, 1 jumper, interferes with drilling, the thinner it is, the better the drill drills. To reduce it, there are many sharpening methods... but that’s a completely different story .

I bought a Chinese machine for sharpening drills 4 years ago. Of course it’s crap, but once I got the hang of it... I sharpen drills from 1.5 mm to 14 - no problem

I need to buy one for myself, otherwise I’m suffering with my eyes, the Chinese drills are crap, they get dull quickly even on soft steel

Of course, for small drills, screwdrivers, etc. you need a manual sharpening wall, and for large technical equipment, etc. you need an electric drive, the stone is the main thing...

What diameter should the drill be, and what speed should the sandpaper be set to, so that after sharpening each plane should be immersed in oil for 2-3 MINUTES??

In general, everything is correct, since all the material was taken from special. literature on sharpening cutting tools.

Everything is written correctly, only one point is annoying, namely: “3. Place your left hand with the tool on the rest. Secure the drill with your thumb. With your right hand, grab the shank." In my opinion, this is a sure way to hurt yourself if the drill for some reason hits the sharpening disc. It will be torn down so that it doesn’t seem like much, you might end up without a finger. The reason for this is that your hand is lying on the support and you won’t have time to pull it away. I was taught to hold my hand up. then you can simply reflexively release the drill and pull your hand away.

Everything is correct.

The article is good and competent. But I really doubt that it will be useful to the hostess.

Of course, a reputable author collected the material, but everything is simple, do it at any angle and by eye. The main thing is to reduce the backing and core at the right angle. The author is probably a theoretician, but he did a good job.

Sharpening a drill is a whole science. And not everyone can do it right. Especially the one whose hands have grown out of his ass and are sharpened to fit a dick.

the boys say everything correctly

According to GOST 1759.1-82 (ST SEV 2651-80), the accuracy classes of nuts are A, B, and C, that is, there may not be 60 degrees at the angle with planes, and in this case, one side of the drill can be sharpened 59, and the other 61, and what do we get?

You just make sure it’s symmetrical, and such a tiny amount of one degree won’t really affect the operation of the drill.

Respect and Like to the author. Commentators have more or less normal drills, they cost from 100 rubles. For 30 rubles, China bends aluminum.

Throw away all the tools and learn to sharpen by hand

not everyone has it

At one time, we were taught how to sharpen by hand. There was no mention of all kinds of devices. I worked as a toolmaker, and sharpened an unmeasured amount of drills.

A colleague by profession, I am also a 4th grade toolmaker, but I read these reviews and am surprised that there are no craftsmen, only managers who are armless!!!

I had a colleague who once studied at the workshop to become a tool maker; he could sharpen drills in five seconds.

Sharpening a drill is a world-class problem. Ridiculous.

good and necessary article...

There are people who call an electrician to replace a light bulb in a chandelier. Their right. And this article is for those who prefer to do it themselves. There is a lot of useful information in it. Therefore, thanks to the author. And if you don’t like to make things yourself, don’t read such material, it’s not for you...

PS As for “whether it will be useful to the hostess”, my missus, when I’m on a business trip, will replace the gasket in the mixer, and change the bag on the panel, and replace the thermal paste in the computer. And by profession he is an analytical chemist (PhD, by the way). So “there are women in Russian villages” :-). This is for those.

Thank you.

Good article. Everything is described in detail. I sharpened the drill with a grinder, now I think that I didn’t start doing this before. So many wasted drills.