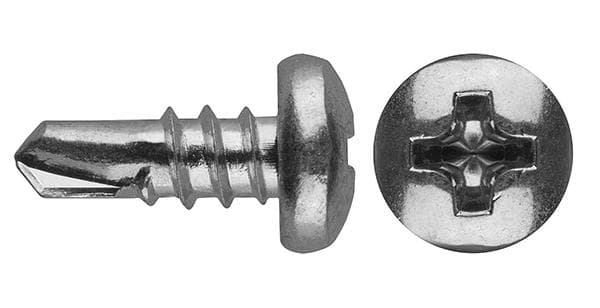

What does the color of the screws indicate? It’s important to know so as not to waste money

Anyone who is not familiar with all the nuances of construction, when buying self-tapping screws, pays attention only to their size and thread pitch; but the color of fasteners seems to such a person to be a purely decorative parameter. Today we will figure out how yellow, white and black self-tapping screws really differ, because it is not without reason that they have exactly that color.

White screws

As a rule, self-tapping screws are made of hard grade steel. Initially they are light gray in color; It just so happened that in this case it is customary to call it white.

Stainless steel is used to make the cheapest fasteners. It has a number of advantages:

- does not rust (high - more than 10.5% - chromium content makes it resistant to corrosion);

- has a long service life - it is calculated in decades;

- strong enough to withstand heavy loads.

Conventional stainless steel screws are used for indoor work if the air humidity does not exceed 65%. Due to their not very attractive appearance, they are often hidden under plaster and other finishing materials.

Another type of white self-tapping screws is galvanized. They are made from carbon steel, so they have increased strength. However, due to the presence of carbon in the iron alloy, such fasteners quickly rust. To prevent corrosion from “eating” the metal, a layer of zinc is applied on top using the galvanic method.An additional advantage of galvanizing is that it gives the metal a noble silvery tint.

It is believed that galvanized self-tapping screws can be used both indoors and outdoors, but experienced craftsmen do not recommend using them to fasten parts that in the future will be exposed to frequent and prolonged exposure to moisture.

Yellow screws

There are two types of yellow self-tapping screws on sale, and most often galvanized fasteners have this shade. You were probably surprised, because a few lines above it was said that a layer of zinc applied to the metal ultimately gives a silver color. However, chemistry is not an easy science and sometimes allows you to create miracles. It is enough to treat silver self-tapping screws in a special passivating solution so that a yellow conversion film about 0.5 microns thick is formed on them. The composition of the mentioned solution includes salts of chromic acid, therefore this process of chemical “coloring” of the metal is called chromate passivation.

Passivation is carried out not only and not so much for the sake of achieving a decorative effect, but to increase anti-corrosion resistance. However, the beautiful color is the reason that yellow self-tapping screws are mostly used for finishing work, for example, for attaching door hinges and other parts visible to the eye.

More expensive fasteners are made from brass (a copper alloy that also includes iron, nickel, lead, manganese, and zinc). In comparison with their steel “brothers”, they win in several ways:

- have increased wear resistance;

- do not corrode even in the absence of protective coatings;

- have non-magnetic properties;

- remain reliable even under prolonged exposure to low temperatures.

Galvanized and brass yellow self-tapping screws are easy to distinguish - the former have a brighter, shiny, sometimes even rainbow color, while the latter look less attractive.

Black screws

Black self-tapping screws are one of the most popular. They are made of carbon steel, and the formation of a dark film on the surface is achieved in different ways.

Black galvanizing

The first method is the so-called black galvanizing. This is one of the types of chromatization. The thickness of the chromium layer can vary from 0.25 to 1 micron, providing, accordingly, varying degrees of corrosion protection.

When buying black screws, it is better to choose those that have been oiled - their resistance to rust is much higher. But in any case, fasteners coated with a layer of black galvanization are not intended for use in conditions of high humidity or in aggressive chemical environments.

Oxidation

The second method is oxidation. The oxide film formed on the surface of the metal is designed to protect it from corrosion, but copes with its task “C”. However, its anti-corrosion properties are slightly higher than those of black chrome film.

Oxidized screws can only be used indoors with low humidity levels.

For use in more severe conditions, the fasteners undergo additional processing:

- oiling;

- hydrophobization.

As a result, a coating is formed on the surface that repels water molecules. Most often, oxidized fasteners are purchased if there is a need to paint them in a specific color.

Phosphating

The third method is phosphating.The film with a thickness of 2–15 microns, formed on the metal as a result of this process, has the lowest decorative qualities, but provides good protective properties. This film consists of iron phosphates, and a powder called Majef salt (a mixture of manganese, iron and phosphorus) is used to apply it. The phosphate film is bonded to the surface of the screws at the molecular level, so it is almost impossible to damage it mechanically. In addition, paint adheres well to it.

Such fasteners are suitable for fastening materials at high humidity.

If you know that exposure to moisture will be prolonged, you should give preference to phosphated screws treated with hydrophobic substances.

Please note: there are also black self-tapping screws, the color of which is a result of simple painting and not anti-corrosion treatment. Check with the seller what metal they are made of and what qualities they have.

Now you can certainly buy exactly those self-tapping screws that are best suited for the task you have in mind. Choose the fasteners correctly, because the reliability, durability, and often safety of the structure depends on it.

Steel is an alloy of iron and carbon, so all steels contain carbon, both cast iron and alloy steels, and steel does not rust due to the addition of certain elements to the alloy

Steel is called an alloy of iron and carbon, there are 3 types of steel: low-carbon with a carbon content of up to 0.25% carbon, then medium-carbon with a carbon content of up to 0.45% carbon, and high-carbon, with a carbon content of 0.5 to 2%, over 4% carbon is someone else's cast iron.. The author is lying a little; all screws are made of steel 5, only some undergo normalization, and some simply go into use after manufacturing. Galvanizing and bluing, as he called blackening, go through galvanizing. Basically, all self-tapping screws are made in China, made from powder metal; as far as I know, there are no factories in Russia for the production of self-tapping screws

Kikh glands.

We make self-tapping screws, no need to lie

The PINK theme is not revealed. ?

sit down-5

“Adding CERTAIN ELEMENTS to steel” is stainless steel.

In other cases, they try to provide protection against corrosion with various types of coatings, and which one is more durable (and cheaper, which is important), here the choice is up to the manufacturers, the price and the consumers.

The most expensive ones presented in the article will be self-tapping screws made of brass and A4 stainless steel, followed by A2 stainless steel (there is no point in describing more expensive types of stainless steel, those who use them don’t read such crap). Next come the universal self-tapping screws, which differ only in the color of the zinc and the manufacturer. The cheapest is a black self-tapping screw.

A self-tapping screw and a screw are completely different things

Alexei. Are you a pro at dealing with screws?

Yes

Tell me how to walk 200 cm of cotton wool. And so as not to rust

200 cm min. cotton wool ????….. Rinat, this is 2 meters min. cotton wool???

Rinat, go ahead boldly, don’t be afraid, it won’t rust. I bet I saw the boys passing by.

Do you guys have any comments... I was racking my brains for a long time... But I did it

Lech, I’ll listen to you too

Sandwich panels are attached white, which means they do not rust

The colors on the screws are galvanized

Interesting and useful article! In principle, store consultants also advise choosing not only the size and pitch of the screws, but also paying attention to the purpose of the screws, and therefore their color.

Well, now I’ve learned which screws for drywall are best in color and which ones for fastening outdoors. Thank you!!!

For gypsum fiber boards/gypsum plasterboards, they didn’t show any self-tapping screws at all!

Self-tapping screws of different colors have different strengths. For example, it is much easier to unscrew the head of a black screw than a yellow one.

In Finland, black ones are generally prohibited from being used in construction, and they don’t even exist there,

But if the inspector finds one somewhere, the Object will not accept...

Not the head, but the head

I buy all the fasteners in Japan, their quality and price are lower, 65 mm. galvanized ones cost 40 kopecks apiece, but black ones like ours, there are almost none there

tell me where you order

Konstantin, where do you buy Japanese screws? There is a link

He just sees the hieroglyphs and thinks “oh Japanese!”

Tell me how to quickly go to Japan

In corrosion-resistant steels (stainless steel), chromium is tenths of a percent, not whole tens. Stainless steel self-tapping screws will be plastic, that is, over time they will “stretch out”, and the price is by no means equal to steel ones, much more expensive.And the rest is about hydrophobization, hydrophobization with phosphating - this does not apply to self-tapping screws. There are three types of coatings on store screws: chemical ox is black, zinc is white, and zinc with chromation is yellow. Brass contains more copper in its composition, and other impurities in hundredths. Therefore, brass screws cannot be stronger than steel screws.

And if you work with wood outside, you need to use galvanized screws, and before installation, dip the end of the screw in oil. Good luck to all.

PS. Rinat wanted to write 200mm.

Stainless steel starts from steel 40X13, where carbon in steel is 0.4% and chromium 13%. The author is right that stainless steel contains at least 12% chromium additive. I can tell you what kind of steel seal combat knives and bayonet knives are made of, it might come in handy. Nowadays there are no knives in stores, but every knife comes with a passport. It shows the composition of the steel. So the best knives are made from steel 90X20, 90X18, which contains 0.9% carbon and 20% chromium

Steels that contain at least 12% chromium are considered stainless steel!!!!!! What tenths of a percent?? Open any reference book and look at the composition of stainless steel

At least 13%, sorry typo

I ask you not to confuse alloy steels and stainless steels; stainless steel is steel that does not oxidize in principle. they contain practically no carbon. example 08x18N10t

Just in case, we all and everything around us is mostly made of carbon, learn chemistry... and everything else is just an addition.

Interestingly, it is written about stainless steel screws - the cheapest fasteners, but have you seen the prices for them?

I was surprised too. I’m also wondering what kind of load needs to be placed on a stainless steel self-tapping screw to make it stretch? For dynamic loads, only bolts and rivets.

I’ve never seen stainless steel self-tapping screws, the author is a bit dumb, they would be worth it, don’t worry. Because chrome is a hell of a lot of money.

Stainless steel self-tapping screws are not uncommon but cost 3 times more than regular ones

My grandfather's house was assembled without nails or screws, in a joint, in a wedge. Not only does it all hold tightly, you’ll never know how to take it apart, I couldn’t knock out the frame with a sledgehammer. And today's youth assemble Mauerlats using screws.

Yes, they really do, they do! (and not just the young people).

I ALSO IN THE CHURCH BUILDING DISASSEMBLED THE FRAMES AND BOXES. EVERYTHING WAS MADE IN A DOVE TAIL. HOW DID THE MASTERS MANAGE TO DO THIS? I HAD TO SAW WITH A SAW AND CUT WITH AN AX, OTHERWISE IT WOULDN’T WORK. AND TODAY IT’S JOINT TO JOINT AND A PAIR OF ITSELF REZOV

+FOAM.

Ha, I live in a wooden house like this, it’s 103 years old along the docks, and my grandfathers back in 95 said that it’s already 200 years old. AND

I was dismantling a log house... I also didn’t know how to do it... cope with the locks... From the corner... I lifted a log with an ax... tied a rope to it, which a friend was holding while on the ground... I climbed onto another log... which is lower ..a friend pulls..the log falls...It’s certainly not fun to climb at the top...but who has it easy...I had to tinker with the window..I just couldn’t understand..and there it turns out the log was cut all the way through and a wedge was inserted

It’s just that over time the house sank and “squeezed” the frame with a death grip.

The cheapest ones are made of stainless steel..., yeah :)

thank you. Wow. healthy !

Yeah, the author screwed up with stainless steel, it will always be more expensive.

But for me, these are screws, self-tapping screws should have cutting edges at the end, like a drill. How can you call screws self-tapping screws??

The screw has a wedge shape, and the self-tapping screw has the same diameter almost the entire length. A self-tapping screw with a drill, that’s how it’s spelled according to the nomenclature. With a large head - a self-tapping screw with a press washer.

By the way, yes. I remember how these hardware appeared in the late 80s and they were much more expensive than our screws, and at first we rarely used them, quite right - we called those with a drill self-tapping screws, but then they all began to be called self-tapping screws.

AGREE

Yellow, black, white... Their color is just a coating and they are all made of the same material. They have completely different application indicators.

Length, diameter, thread size. That's all. This is the first time I’ve heard about stainless steel self-tapping screws. But maybe I haven't been to the shops for a long time. They have no practical meaning.

Stainless steel self-tapping screws exist. They cost more than everyone else is used to. At construction sites they are used to fasten facade structures. In most cases, "grouse". Of course, they are purchased from large suppliers and with the obligatory attachment of a certificate. At a construction site, in general, all the material is certified (this means complex construction, not a private shed).

I don't agree. Yellow self-tapping screws are made of mild steel, black ones are hardened. Nobody assembles a roof using black screws!!!

You spoke well about knives. But the article is about SCREWS! I agree with Gennady (01/16/2021).

And what kind of animals are cats that make knives? :))))

Grumpy! There is no word for golvanika in the Russian language... There is galvanika!

Friends, the main thing is not to buy ARMENIAN ones. Half to throw away. Anyway..

Kikh glands.

I work at a factory in the hardware workshop, we produce up to 700 tons of self-tapping screws per month, the quality of ours is much higher than the Chinese ones. Regarding the article - there are some inaccuracies, but for the common man it is quite

All screws are made from the same steel. Like Art 45 or analogues with subsequent heat treatment. And galvanized. Many people, when tightening self-tapping screws, have encountered the effect that the heads break off or the threaded part breaks with a hammer blow. This is the first sign of a production defect, overheating. Like

known from metallurgy. With increasing hardness. The hardness of the metal increases. At the same time, the fragility of the metal increases.

It's a miracle of the 21st century how we managed without them before

Self-tapping screws are not made from stainless steel! Stainless steel made in the USSR is not magnetic. And as you know, self-tapping screws magnetize everything, even bits are magnetized specifically to hold them.

The stores are full of stainless steel screws. And there is magnetic stainless steel, for example 40X13.

There is a stainless steel that is magnetic, with a low content of alloying agents.

Stainless steels are either magnetic or non-magnetic (depending on the set of additives and purpose)

Where are you? Go out into people. There have been stainless steel self-tapping screws for a long time now. We use them ourselves.

the other day I bought black self-tapping screws (blue black 75mm) in a store in my village, they tear and bend... I bought the exact same ones in another store, only they are a little greyish... the class worked without problems...

Steel, like cast iron, is an alloy of iron and carbon, and they differ not so much in the carbon content in the alloy, but in the aggregate state of carbon (this mainly depends on its amount in the alloy). If carbon is completely dissolved in iron, forming the so-called. eutectic, then such an alloy is called steel, and if the carbon in the alloy precipitates in the form of graphite grains, then this alloy is called cast iron. The minimum value of carbon content at which it can precipitate in the form of graphite grains of various shapes is 2.4%. Therefore, in metallurgy, it is customary to consider alloys of Fe with C with a carbon content of up to 2.4% as steel, and above this value as cast iron. But there are steels that have a eutectic structure with a carbon content of even 4% and higher. An example is blade steels, which require high blade hardness and high bending strength. This is another story related to steel alloying and special heat treatment at different stages of technology.

Self-tapping screws are different from screws. 1.Philips slot (PH2) Clean floating cross. 2, thread pitch, on average 45g. The body of the self-tapping screw is thinner. The coatings are varied, phosphated black, galvanized, yellow passivated, etc. Screw. 1, Spline Pozidrive (PZ) 1,2,3, double cross with notches. The body is thicker, the carvings are more frequent. All coatings except black. In simple civilian conditions, there is no need to use stainless steel. Expensive, not sold everywhere, and there’s no need.

Disagree.purch praise

The main manufacturer is China. Self-tapping screws with markings on the slot are of better quality. Letters from A onwards. Light black grays are the most fragile

Stainless steel - there is no such term

In Russia, the terms are an everyday concept, like Xerox Samsung - HP? so does the Jeep - everything that is larger than the Niva.

Yeah - I somehow agreed to meet with a person. I call him - he says - I have a Volkswagen jeep. I just wanted to be sarcastic - do you have a Jeep or a Volkswagen? It’s also infuriating when large TVs are simply called “plasma,” which is based on completely different principles and has not been produced for a long time.

Stainless steel self-tapping screws are sold in the store, I mainly use them when assembling shower cabins and attaching shelves of hangers in bathrooms, yes they cost money but they turn out very neat and practical

After reading about “cheap stainless steel screws” I lost interest. Stainless steel is by no means a cheap material.

Steel can't help but rust! It's just that the corrosion rate is different.

Stainless steel screws are very easy to identify; they are not magnetic

I especially liked the end of the article. Ask the sellers. They are stupid to distinguish by size, but here is the composition and methods of coating. Have you seen the description of screws on the packs? I don't see anything other than size. Why does the buyer need it? It’s clear that you can’t buy stainless steel in a regular hardware department. If you need a siphon screw, for example a longer one, then we have a specialized store. Sells all types of stainless steel fasteners.

Where is the screw in the siphon?

Nothing else to talk about?

Try about nails.

Yes, really very “important” information))

But I still didn’t see the conclusions and the small comparative plate...

And where the composition of the screws is written on the packaging, suppliers usually do not write anything

About the black self-tapping screws, when you screw them in with a screwdriver, their heads fly. There are gray ones, they have strong heads. And I don’t know which group they belong to. In general, I'm trying to buy gray ones.As for the consultants in stores, I’ll say this: not all of them know the quality of self-tapping screws..

As a rule, black under the bat PH white PZ

How to put diz?

In technology there is no concept of “strong” steel. Metal can have hardness or strength. The term "strength" refers to alcohol.

Miss, let's go and help these screws, along with the bolts, maybe we can find a pink one or a green one with a blue tint

Natalia has the most competent comment, the rest are demogogs or profane.

But I’m not at all interested in how much carbon is in self-tapping screws, something else infuriates me - why do greedy hucksters in stores sell them individually and not by weight? At the base they buy in kilograms or boxes, and the bastards sell them individually. You stand there like a tree stump and wait as they count out 100 screws for me.

You can see for yourself that they are hucksters, and even greedy, I bought half a cube of 3-meter boards, so I measured the length of each, where it was 3.05, where it was 3.04, and where it was as much as 3.10, I calculated everything!!!

The most important thing is that black self-tapping screws are very fragile to break and twist, all the others are more flexible.

You can start with the fact that if I have a silver frame, I will screw it with white screws, and not black or gold. Also with a hanger, door handles. Steel is important in knives... Which can be sharpened like a razor. And for self-tapping screws, hardening is important so that when screwing and unscrewing, the slots on the head do not get worn out and the heads do not fly off.

PS. And I’ll tell Leon... There is a strong handshake and strong friendship, and not just alcohol.

If we really do, then we need to talk about the mechanical properties of the screws and the material that they hold together; and how these screws work against shear, impact, tension, and fracture; and how far the screw should go into the parts being fastened in order for the connection to be strong and reliable; and about which screw heads are more reliable and technologically advanced; and about what is called stainless steel; and much more about!!!!!

I would tell you more about fragility. a long time ago due to lack of experience, I don’t often work with self-tapping screws, I assembled a ladder from black ones) I was good in ankle boots, otherwise my leg would have suffered more

in principle, I thought I’d find out about the mechanical properties, so I went in, but didn’t find what I was looking for

Good day. Having read the comments and many here are mistaken about stainless steel self-tapping screws, take any purchased so-called stainless steel self-tapping screw and start heating it until red hot, now repeat the same thing but with real stainless steel. you will see the result that a self-tapping screw made of stainless steel is not stainless! I won’t give all the details, just do it on willow, you will see how smart people will lose their self-esteem here. I am a gas cutter and I know how stainless steel and other metals behave when heated. oh yes, what you see with the so-called stainless steel self-tapping screw during heating, look at the result on the Internet or in books “properties and marking of metals”, so that there is no dispute.

This is understandable... What is the difference between PH and PZ?

Antarctica, better write about borscht?

Yeah, there’s a lot of incorrect information and a mismatch between the pictures and the text.

Even the head of the self-tapping screws that are handed comes off if the frame moves, it’s safer with nails!!!

I play brawl stars and was looking for normal screws!

/*

“Now you can certainly buy exactly those self-tapping screws that are best suited for the task you have in mind.”

I present the picture. You come to the store and ask the seller - how were these self-tapping screws treated, oxidized, galvanized or phosphated, and did they undergo passivation?

The seller looks with round eyes and shrugs his shoulders - what was that just now?

Definitely, now we will all buy exactly those screws that we need...

Lelik agrees with you

Yes

The author never fully covered the topic. It was necessary to indicate for what material and which screws it is better to use. For larch, it doesn’t matter what the screw is made of; any one will break off if you don’t drill it first...

Self-tapping screws are screws, I looked at a lot of material on this topic, and came to the conclusion that, by and large, no one really knows what the difference is. In my opinion, the difference is only in the name and not in the quality of the metal or the color of the product, there is no fundamental difference, I would call self-tapping screws only products with the shape of a screwed end in the form of a drill, which actually drill a hole. It’s just that in the Union they didn’t produce self-tapping screws, but only screws; with the advent of foreign technologies, the fashion for self-tapping screws also came. I would like to see a qualified response to this topic from the manufacturers of these hardware.

On the seashore there is only stainless steel.

Brass ones are less durable. Do not use.

Everything else rusts within 3-5 years.

Yellow self-tapping screws

The most competent review from the Article!!!!

Conventional stainless steel screws are used for indoor work if the air humidity does not exceed 65%.Made of stainless steel indoors with humidity not higher...??? Damn, then you can’t use any outdoors at all. Any coating is destroyed. But stainless steel does NOT rust, does not oxidize, and is chemically resistant, if it is truly stainless steel. And stainless steel can be magnetic.

Butter. We need to be more specific. From your article it is not clear that there is a difference where self-tapping screws can be used. About durability. What observations and experiments did you conduct? For how long (10, 20, 30, 40 50 or more years)?