Composition and instructions for use of BF-2 glue and BF-4 glue, taking into account their technical characteristics

Content:

- Where and when are BF-2 and BF-4 used

- Specifications and components

- Methods and rules for preparing metal surfaces before using BF-2 and BF-4

- Methods of using adhesives BF-2 and BF-4

- Instructions for using the hot gluing method

- Instructions for use: how to cold glue tiles

- How can I replace glue brand BF-2 and BF-4

- Storage and transportation

BF-2 and BF-4 glue is an industrial structural adhesive designed for high-strength gluing of almost any metal, polymer and leather products. The composition is based on phenol-formaldehyde resin, polyvinyl butyral and ethyl alcohol. The listed components are contained in BF-2 and BF-4 in different proportions.

Where and when are BF-2 and BF-4 used

The scope of their application has virtually no boundaries. Due to their high-strength adhesive composition, adhesives of the BF-2 and BF-4 brands are widely used in the electrical and radio engineering, aviation, construction, furniture and packaging industries. They are distinguished by their high ability to withstand heavy loads and vibrations, which makes them indispensable in the production of such pressed materials as chipboard, plywood, and multilayer plastic.

In the household, BF-2 and BF-4 glue is widely used for repair, construction and household needs. Information on which adhesive is most suitable for gluing specific materials is given in the table:

| BF-2 | BF-4 |

| hard static materials | elastic materials that are flexible to bends and vibrations |

| non-ferrous metals, stainless steel, non-metals with metals | |

| pressed plastic | textolite |

| ceramics | plexiglass |

| glass | tree |

| granite | Chipboard |

| marble | linoleum |

| porcelain | Leather Products |

| natural stone | rubber products |

| tile/tile | electronics/household appliances |

| Due to the content of toxic substances, glue is not used for gluing dishes! | |

Both types of glue are used very rarely for impregnation and varnishing of surfaces, with the exception of small-sized products that require restoration work.

Specifications and components

The main component in the BF-2 and BF-4 adhesives is the synthetic polymer polyvinyl butyral, which is formed by the interaction of two substances - polyvinyl alcohol with aldehyde. Polyvinyl butyral makes the adhesive elastic; its percentage in the adhesive is indicated by a number next to the letters “BF”. Therefore, BF-4 brand adhesive is characterized as more elastic compared to BF-2.

It is important to note that the higher the elasticity of the adhesive composition, the lower its strength and ability to glue hard and static material in structure.

Other components included in the glue:

- ethyl alcohol is a substance that is used as a solvent;

- phenol-formaldehyde resin is a substance that consists of aldehyde and phenol and is used as a thickener.

The appearance of the adhesive composition of the BF-2 and BF-4 brands can be transparent or cloudy with a light yellow or reddish tint. There is no difference in the viscosity of the adhesive liquid.

Other significant characteristics are presented in the table:

| Glue brand | Heat resistance | Film bending elasticity | Strength | Resistance to aggressive environments |

| BF-2 | from -60 to +80℃ | 3 mm | 19.6 MPa | oil, fuel, alcohol, acid, alkali |

| BF-4 | from -60 to +60℃ | 1 mm | 19.6 MPa | acid, alkali, salt fog |

The viscosity of the composition of the adhesive liquid grades BF-2 and BF-4 can increase under the influence of sub-zero temperatures. Before use, such glue must be kept at a temperature of 21-23℃ at least 3 days.

Methods and rules for preparing metal surfaces before using BF-2 and BF-4

The surfaces to be bonded must be thoroughly cleaned of dirt and dust. Experts recommend removing the following possible impurities and defects from surfaces for a strong adhesive bond:

- burrs/sharp protrusions;

- burn/corrosion;

- welding spatter

- roughness;

- oil/grease stains;

- paint coatings.

There are two methods for cleaning metal surfaces - chemical and mechanical. In case of severe contamination and the presence of corrosive formations, it is recommended to clean the surfaces using chemical and mechanical methods.

- Mechanical method. The surfaces of non-ferrous metals are cleaned with an abrasive with a permissible grain value of 15 to 20. The surfaces of ferrous metals are treated with sandpaper with a grain size of 63 to 80. Cleaning of surfaces and welds is carried out manually or using a grinder and an abrasive disk attachment.

- Chemical method. During chemical treatment, the surfaces of the samples are thoroughly wiped first with gasoline, then with acetone. After processing, metal products must dry thoroughly.

When gluing metal samples and parts, the air temperature in the room should be no lower than 15℃ and no higher than 30℃, and the air humidity should be no lower than 60% and no higher than 80%.

Methods of using adhesives BF-2 and BF-4

The hot gluing method allows you to create a high-strength and resistant seam to the influence of an aggressive environment. If the product will not be used under conditions of increased exposure to artificial or natural negative factors, then gluing can be done using the “cold” method.

The table shows an approximate list of materials that can be glued using cold and hot methods:

| "Cold" method | "Hot" method |

| Leather Products | Non-ferrous metal |

| Rubber products | Black metal |

| Glass/plexiglass | Marble |

| Wooden crafts | Porcelain |

| Pressed wood/plastic | Granite |

| Ceramic products | Natural stone |

Instructions for using the hot gluing method

The glue is applied to one surface of the material, with the exception of cases when it is necessary to obtain a super-strong seam, for example in butt metal joints, when gluing products of large dimensions, as well as in cases where the glued samples will subsequently be used under conditions of heavy loads or in negative conditions. environment.

Step-by-step instruction:

- The glue is applied in one layer to the bonded surfaces of the product at room temperature not lower than 15℃ and not higher than 30℃ and left to dry for 50-60 minutes when using BF-2 brand glue or for 40-50 minutes when using BF-4. If the weather permits, the products can be kept in the air.

- Apply a second layer and connect the parts together. For good adhesion, the parts are additionally clamped using a lever press or pressed down with a clamp. When using BF-2 glue, the fastened parts are sent to a drying cabinet at a temperature of 130-140℃ for 60 minutes. For BF-4, the temperature in the drying cabinet should be within 150-170℃, and the drying time should be 40 minutes.

- After drying, the products are cooled to room temperature within 24 hours.

Glue consumption for double application should be 60-80 g per 1 m2 surface to be glued. Products should be kept in a well-ventilated area or with good ventilation until completely dry.

Instructions for use: how to cold glue tiles

The proposed step-by-step instructions for cold gluing can be used equally when working with BF-2 and BF-4. The choice of glue depends on the material of the product.

| Illustration | Step-by-step instruction |

|

Stage 1. To work you need to prepare:

BF-2 glue; an empty tube for glue with a pointed tip for convenient and accurate gluing of the end parts of the tile; acetone for surface cleaning; soft rags to remove excess glue. Sandpaper is needed to clean surfaces.

|

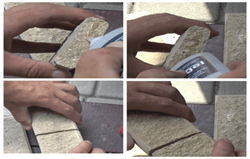

|

Stage 2. Treat the end parts of the tiles with acetone. There is no need to grind and grind the ends before gluing, since the break line on one half of the tile coincides with the break line of the other half. After treating with acetone, both halves should dry for 5-10 minutes. Pour the glue into an empty tube with a sharp tip and prepare a napkin to remove excess glue. |

|

Stage 3. Apply the first layer of glue to the end parts and leave for 20-30 minutes. After 20-30 minutes, the ends are coated with a second layer and again left for 10-15 minutes. |

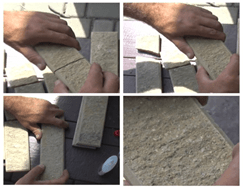

| Stage 4. Connect both halves, remove excess with a cloth. The connected halves must be held in your hands for 2-3 minutes, applying pressure on both sides. | |

|

Stage 5. The glued tiles must be placed on the oven door, heated to 180℃. The time to warm up the glued seam is approximately 40-50 minutes. Next, the tiles are left for 24 to 48 hours at room temperature.After 1-2 days, the tiles are considered suitable for use. |

How can I replace glue brand BF-2 and BF-4

It is difficult to find similar adhesives, since phenol-polyvinyl acetate adhesives have a patented and unique composition. An adhesive called “Super Cement” has similar qualities, but this product is much inferior to glue brands BF-2 and BF-4 when working with metal products.

Some experts recommend, as an analogue, products made on the basis of epoxy resin. Epoxy glue, for all its advantages, has significant disadvantages - rapid drying and low resistance to aggressive factors such as acid and alkali.

Storage and transportation

It is recommended to store the glue in a dry, dark place out of reach of children. The adhesive must be kept in its original packaging and away from any source of fire.

Transportation of the product is carried out in accordance with the requirements for transportation of explosive and flammable materials. According to the requirements, the product, subject to all rules and regulations, can be transported by road and rail. Transportation can be carried out in steel and metal barrels, flasks and tanks.