Types of epoxy glue and rules for its use

One of the most important tools for people who do repairs is glue. Use it to fix wallpaper and tiles. It is also useful for connecting different parts. But many people think that this is not a reliable enough remedy. They just never heard of epoxy glue. It is made from epoxy resin - this is a substance with a specific consistency. When other elements that make up the glue are added, the resin hardens. In solid form, it reliably holds together various objects and parts. Thanks to its characteristics, epoxy adhesive has been used not only in the domestic sphere.

Types of epoxy glue

Even a product like epoxy glue comes in many different types. The main criterion for division is the form in which the product is sold.

- One-component. It consists directly of resin and special substances. This glue is sold in the form of a ready-made mixture. True, in terms of its bonding properties it is somewhat inferior to the next product.

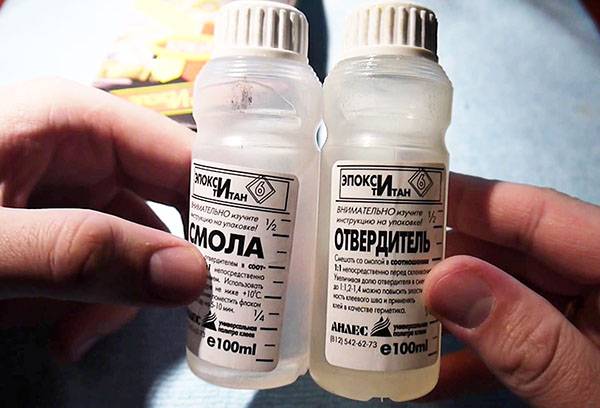

- Two-component. It is not sold in finished form - the set consists of two tubes. One is filled with resin, and the other with a substance due to which the composition will eventually harden. And they must be mixed immediately before use. The finished product hardens quickly and securely fastens the parts.

Individual classes of glue differ in their consistency:

- paste glue. It is usually found in the form of one-component or two-component formulations;

- plastic mass sold in blocks;

- film glue.

The glue also differs in some other properties.

- "Moment" produces a special transparent composition. It is universal - glue in a large container is suitable for repairs, and with the help of the substance in a convenient tube you can, for example, glue a broken vase.

- “Contact” produces epoxy glue, which is highly resistant to moisture and is suitable for things that are constantly in contact with water. At the same time, it holds any materials together.

- EDP glue is more suitable for serious construction and finishing work. It is also versatile and can bond any materials. But, for example, it should not be used for dishes - even a small particle of resin entering the body is dangerous to health.

- For metal objects there is a special glue called “Cold Welding”. As the name suggests, this product can replace welding. It is even better, because it can handle a large number of alloys.

Where is epoxy glue used?

Regardless of what type we are talking about, epoxy adhesive is used in a huge number of areas.

- Construction. This, of course, also includes internal repair work - gluing tiles, fastening metal and concrete. But epoxy is also used for larger-scale tasks, such as gluing reinforced concrete elements in bridge construction, joining panels, and strengthening concrete by filling cracks with resin.

- Automobile production and repair. Brake pads are secured using epoxy resins. The substance helps to glue plastic elements onto metal surfaces. Epoxy will help restore the gas tank, gearbox, trim, and body.

- Aircraft construction. Here, resin is used in conjunction with welding or even instead of it to secure elements at joints. And with the help of this product, thermal protection is installed inside and outside the case.

- Shipbuilding. Epoxy is also used here - both for securing various elements and for external processing. After all, as mentioned earlier, certain types of glue are especially resistant to moisture.

- And, of course, this tool will also come in handy at home. It can be used to repair dishes, shoes, and furniture. Epoxy has also found application in needlework.

Properties of epoxy two-component adhesive

In addition to the resin itself, the finished epoxy also contains a hardener and a solvent. During production, established rules are always followed.

It is important to maintain the correct proportions of epoxy resin and hardener to obtain an adhesive with the required properties.

- A distinctive feature of epoxy is its resistance to high temperatures (even to prepare the composition you have to heat the resin very much). The product is also resistant to low temperatures.

- The glue will not be damaged if various oils or gasoline come into contact with it. This is especially important when epoxy is used to seal joints.

- Various cleaning products that are used for cleaning will not cause any harm to it.

- This glue is very elastic - if the elements that it connects move slightly after hardening, the substance does not crumble and continues to hold the parts together.

- Hardened glue does not shrink over time and cracks do not appear on it (it is not for nothing that it is used to seal cracks in concrete).

- Does not allow water to pass through (although this property is enhanced with the help of additional additives).

Not all properties are positive.

- The composition hardens quickly, so you need to use it very carefully.

- You need to wear protective clothing when working with it, since it is extremely difficult to wash hardened glue from the skin.

What temperature can the glue withstand?

Separately, it is worth mentioning the temperature regime at which the glue is able to retain all its properties. Even to work normally with a substance, it must be heated. Operating temperature is about seventy degrees.

Advice

To heat the resin, the container with it must be placed in a basin filled with water at the appropriate temperature.

- The maximum temperature for glue is plus two hundred and fifty degrees.

- The lowest is minus twenty.

This stability is one of the reasons why epoxy adhesive is used not only in domestic conditions, but also in the production of cars, the construction of aircraft, ships and bridges.

How to dilute epoxy?

Before using glue, you need to figure out how to dilute the resin and additional substances so that the composition meets the standards and has all the properties.

- The resin is usually very thick. Mixing it with a hardener is problematic. Place the tube or bucket in advance in a basin of water heated to seventy degrees. The same applies to the finished one-component composition - if you heat it, it will be much easier to work with the glue. But it is important that water does not get into the resin.

- You also need to prepare a vessel in which you will mix the substances. Choose one that you don’t mind throwing away: once it comes into contact with the resin, you won’t be able to wash it off and it will become unsuitable for further use.

- Now you can dilute the glue. Pour the resin into the container and add the hardener to it, stir well. Standard proportions are ten parts resin and one part hardener.But along with the product there should be instructions for use. For some varieties, the ratio is different - five parts resin and one part hardener.

- From the instructions you will find out how long it takes for the finished composition to dry. Usually about a day, but sometimes less.

- Use caution and protect your skin.

How to use epoxy glue?

You also need to know how to use epoxy glue correctly. When you need to connect two parts or glue an element to a surface, apply glue to only one of the objects. Then press it against the other and fix it. You need to hold them for about ten minutes. After this you need to leave it to harden. This will take about a day. Do not forget to ventilate the room in which you worked with epoxy.

Conclusion

Epoxy resin glue is a universal product. It is useful for fixing a broken vase, but it is also used in the construction of bridges and airplanes. There are several types of glue. In particular, it is divided into one-component and two-component. The latter is simple to prepare and more reliable, so this type is more often found in stores.

It is important to be careful when using glue as it is very difficult to wash off the skin. And in general, it is harmful to the human body, so do not use it to repair dishes.

Remember to follow the proportions when preparing the mixture. This is the only way you will get glue that will securely fasten the parts.