How to work with epoxy resin correctly and safely?

Epoxy resin is used in the manufacture of insulating materials, fiberglass, and the compositions are used for waterproofing and coatings exposed to moisture and aggressive substances. The solution is poured into molds and various products for industrial use and design work are obtained.

Composition and properties of the adhesive compound

Depending on the components, the connection between the parts can be strong and rigid or soft and elastic, like rubber. After polymerization, a reliable seam is obtained. A dried polymer cannot be dissolved or melted; the connection can be called eternal. The resulting products can be used in bedrooms and children's rooms: the hardened epoxy resin does not emit harmful substances. If you need to glue materials with a smooth, pore-free surface, it’s hard to think of a better solution.

Various substances are used as hardeners. Their selection depends on the connection requirements, operating conditions of the product and many other factors. As a polymerizing agent, on which the characteristics of the glue largely depend, you can use:

- phenols;

- tertiary amines;

- polycarboxylic acids.

Epoxy resin is a general name for a two-component adhesive, and there are different brands and compositions of the product. For household use, brands that can dry at room temperature are usually used.In production, sometimes you need to work on a hot surface, in conditions of high humidity or exposure to an aggressive environment. Depending on the composition of the components, you can prepare a solution that can create a strong connection both at a temperature of +200⁰C and in sea water.

How to dilute epoxy resin correctly?

If you don’t like to prepare a working solution and want to open the tube and immediately coat the surfaces to be glued, epoxy resin is not for you. It does not glue anything itself - to get a reliable connection, you need to add a hardener and mix the composition well. The ratio of components depends on both the type of resin and the composition of the hardener. If you make a mistake in the ratios, the product will not be strong enough and will become less resistant to temperature changes, moisture and other conditions. The correct composition must be prepared according to the instructions, which describe in detail how to dilute the epoxy resin.

One type of epoxy - EDP glue - manufacturers recommend diluting it in the following proportion: 6 parts resin and 4 parts hardener. Other brands have a ratio of 10:4 or 10:6. Pour the ingredients into a special container and mix thoroughly. If the density of the resin is too high and mixing is difficult, warm it up a little in a water bath. If you want to add dyes, use only dry powder pigments. Any drop of moisture can negatively affect the quality of the adhesive.

Advice

To prepare, mix and apply epoxy resin, use utensils and tools that you don't mind throwing away. It is very difficult to clean them from glue, and there is no guarantee that you will wash off the entire composition without leaving a residue.

Sometimes it is necessary for polymerization to take place quickly so that the product can be used within a few hours. It is useless to experiment with the proportions of the composition; this does not affect the reaction rate. It is better to heat the bonded joint, every 10⁰C will speed up the hardening process by 2-3 times. There is a specially formulated two-part epoxy resin that can create a strong bond quickly and at low temperatures.

How to work with epoxy resin, material consumption per 1 m2

In order for the work to be done efficiently, the surfaces should be well prepared. The epoxy resin must adhere firmly to both surfaces, otherwise your project will quickly fall apart.

Before applying resin, perform the following steps:

- clean the surface from dust and dirt;

- degrease the parts with solvent or detergents so that no traces of oil and petroleum products remain on them;

- Treat glossy surfaces with sandpaper or a grinding wheel.

Advice

If you need to make self-leveling floors or other structures of large thickness, apply a thin layer of epoxy resin. When the first coat is hard but still tacky, apply the next coat and repeat until the desired thickness is achieved.

Connect the glue-coated surfaces, press them firmly together and secure. As a holder you can use a strong rope, a vice, clamps, or a weight. The product should remain in this position for about a day until the primary polymerization takes place. Then you can remove the fastener, but you should not subject the connection to loads, the epoxy resin has not yet gained strength.Complete drying usually occurs after 7 days at room temperature.

Often when working, the question arises of how much resin needs to be diluted so that the composition is enough for the entire volume and there are no large excesses left. Approximate consumption is 300 g per m2, but much depends on the thickness of the layer, surface texture and other factors. Do not dilute more than 0.5 kg, because the composition dries quickly and you may not have time to spread and connect all surfaces.

How long does it take for epoxy to dry?

The prepared solution can be used from 30 minutes to an hour, the time depends on the brand of resin and temperature. Once the polymerization process has begun, it is useless to try to stop it with solvents or other methods. All that remains is to throw out the jar of epoxy resin and prepare a new batch.

The product can be used when the polymerization process is complete. The duration of the process depends on the temperature at which the product dries. At +20⁰C, the glue will dry within a day, and the joint will reach maximum strength in about 7 days. At +100⁰C, the polymer is formed in half an hour and fully strengthened in 2 hours.

Sometimes it is necessary to change the color of the epoxy adhesive. You can add pigment to the composition. If you need to epoxy a surface that has been coated with polyester resin, wait until it is completely dry. Try not to apply the compounds in the reverse order, but if you need to apply polyester resin to epoxy, wait until complete polymerization (at room temperature it lasts 7 days), and then sand the surface with sandpaper.

What temperature can the glue withstand?

Different types of epoxy resin are produced, and its quality depends on the composition of the components.For household use, glue with a cold hardener is most often produced. It can be used for gluing products that are not exposed to high temperatures: shoes, furniture, decorative trim. Manufacturers write in the instructions and technical specifications what temperature the seam will withstand.

If you need to stick something on a fireplace, or repair something that is exposed to extreme heat, use a hot-type hardener compound. Be sure to look at the maximum heat the seam can withstand. Epoxy resin is a universal glue, but even it will not withstand the fire of a steel melting furnace; do not expose the joint to too high a temperature.

The same applies to the temperature of the bonded surfaces. To work with epoxy outdoors, glue is produced that hardens at sub-zero temperatures; there are compositions that will set only when heated. Before going to the store, think about the conditions under which the product will dry and be used. The instructions will indicate whether this brand of glue is suitable for your work.

Mistakes when working with epoxy resin

For household use, grades are produced that do not require a precise ratio of resin and hardener. Such compositions are designed to prepare a small amount of solution; a few grams will be enough for you to repair shoes, furniture, or install a mirror in a frame. The recommended proportion is usually: 1 part resin to 1-2 parts hardener, but products vary, be sure to read the instructions. Small doses can be easily mixed by hand in a jar or old bowl, but for larger quantities it is better to use a special mixer.

After hardening, the materials remain glued together forever. It is useless to look in reference books for information about the melting point of the polymerized composition and what can be used to dissolve it. Before the glue sets, think about whether you have connected the parts correctly or whether you need to change their position. Then it will be impossible to correct the error.

If a lot of material is required, difficulties may arise. When mixing large volumes, a strong release of heat occurs and the composition quickly hardens. If the temperature rises too rapidly, smoke begins to be released, and spontaneous combustion of the mixture may occur. When purchasing, ask the seller or read the instructions for what volume of mixture this brand is designed for. For the manufacture of castings, self-leveling floors and other structures that require a large amount of mortar, special compositions are produced. They do not overheat, freeze evenly, without bubbles. When preparing a large volume, you cannot simply add a hardener and stir; the resin must first be heated so that it becomes less viscous.

If the epoxy resin has been stored for a long time and has become too thick and cloudy, place the jar in a water bath and heat it to a temperature of about +60⁰C. Do not use thinners or solvents for this purpose; they are incompatible with epoxy resin - the composition will lose its qualities, and the connection will initially be fragile. Subsequently, the solvent will evaporate, and the polymer will hold the glued parts even worse. If during preparation of the composition the mixture boils and foam appears, glue cannot be used. Prepare a new solution as recommended in the instructions for use.

Advice

Be careful when heating the composition in a water bath.If drops of water get into the glue, the solution will become cloudy and lose its quality.

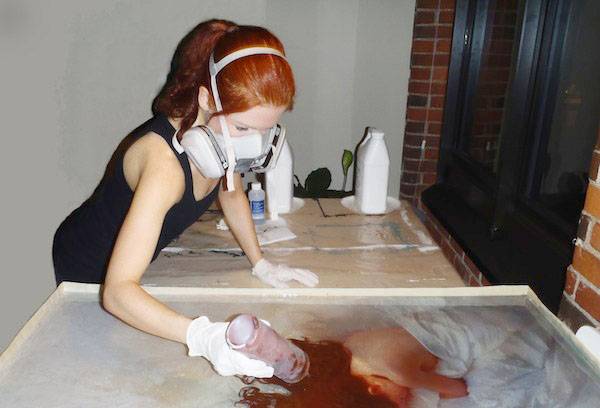

Is epoxy harmful to health?

When frozen, epoxy glue is safe for health and does not emit harmful substances into the air, but when preparing the solution and working with it at home, precautions must be taken. To prevent vapors from irritating your respiratory system, use a respirator. It is advisable to work with harmful compounds outdoors or in non-residential premises. If you use glue in your apartment, open the windows.

The components of epoxy glue have a harmful effect on the skin: they cause burns, irritation, and dermatitis. To protect your hands, wear gloves with protective cream. If the product gets on your body, wipe the affected area with denatured alcohol and wash with soap and water. Do not use food-grade utensils for work; epoxy resin should not come into contact with edible products.

Keep components out of the reach of children and animals. When working, make sure that children do not enter the room and become interested in the contents of the jar. If someone accidentally swallows epoxy adhesive or gets it in their eyes, seek immediate medical attention.

Epoxy resin can be used to glue any product, you just need to choose the right brand of glue for specific work. Gain experience on small surfaces where the composition should be applied in a thin layer. When you learn how to mix components correctly and understand how to dilute epoxy resin without boiling or bubbles, you can begin more complex processes: making self-leveling floors, casting decorative elements in molds. Master different techniques for using epoxy, and then you simply won’t need many other types of glue.

I have long wanted to try making jewelry out of epoxy resin. Thanks for the detailed instructions