What glue to choose for polyethylene and how to use it correctly?

When building greenhouses, installing waterproofing and performing other construction work, a craftsman may need a reliable glue for polyethylene, which will create a strong and airtight seam. Designs and operating conditions vary, and each case has its own requirements for the connection. Pipes and fittings for them are made from polymer. Usually, when installing sanitary products, you don’t have to glue the parts together, but use special connecting parts. When installing waterproofing and many other works, it is necessary to firmly and hermetically fasten the materials together.

Technical characteristics and requirements for the adhesive composition

Polyethylene is loved by builders for its unique properties: the polymer is completely impermeable to moisture and can be used for waterproofing, it is resistant to chemical influences, and aggressive moisture will not damage its structure. Sometimes this material is used for electrical insulation and even for protection against certain types of radioactive radiation.

Polyethylene is good for everyone, but craftsmen don’t like one drawback - it’s very difficult to glue the film to another surface. To understand how to choose the right fastening composition, you need to understand what happens to the materials during the gluing process. Sometimes substances that destroy the structure of the material are used for this work. The surface becomes sticky and firmly connects to another structure.Approximately the same thing happens when welding 2 pieces of polymer or sealing bags. But sometimes it is necessary that the material does not deteriorate and remains in its original form. In this case, the glue molecules, due to the potential difference, must firmly adhere to the molecules of the film and material of a different design.

Depending on the polymer application, bonding requirements may vary. Strength and durability are essential for any job. Environmental characteristics are not of great importance for outdoor structures, but are important when finishing interior surfaces. If waterproofing a shower or bath is carried out, it is necessary that the composition does not deteriorate and does not release harmful substances under the influence of hot steam. The connection in places exposed to sudden temperature changes must be sufficiently elastic so that the thermal expansion of the materials does not break the tightness.

Which method is better?

Polyethylene molecules do not have a high electrical potential, so finding a substance that will stick well to the polymer is very difficult. Not only chemical compounds are used for joining; depending on the type and purpose of the structures, other methods can be used.

Craftsmen have found several ways to create a strong connection.

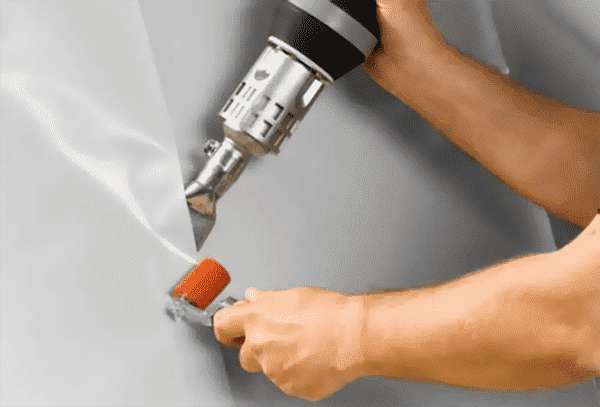

- Welding is used when gluing 2 polymer structures, especially for foamed polyethylene.

- Double-sided tape will help to fasten the plastic film together or attach it to structures made of some other materials, but such a connection cannot withstand heavy loads.

- Special glue.

In stores you can see a lot of ready-made materials, the packaging of which says that they are suitable for gluing polyethylene.Please note that the composition must include methyl acrylate. This component softens the polymer, which is especially important when working with thick films. The composition may also include xylene and chromic anhydride. It is convenient to work with this glue, it is ready for use and does not require additional surface treatment. The only negative is that the vapors are very toxic; you need to work with good ventilation or a respirator.

There are preparations in the form of a thick paste, which must first be mixed with the solvent included in the kit. It is more difficult to use such glue; the working solution dries very quickly. If you do not have experience, prepare the glue in small portions. Epoxy resin has similar qualities, which can be used for gluing foam and ordinary polyethylene.

Reliable manufacturers and brands

To make the connection reliable and durable, you need to use a good adhesive. Companies that value their reputation do everything possible to make it convenient for the craftsman to work with their products. If you don't know what to choose, pay attention to the appearance of the product. A self-respecting manufacturer will never pack the material in a box that tears at the first touch, or stick a nondescript, quickly fading label on the container with blurry text and an incomprehensible design. Look at the instructions. It must be detailed and written in understandable language.

For gluing polyethylene there is a special adhesive Easy-Mix PE-PP from Weicon. It contains microscopic glass beads that give extra strength to the seam. The composition hardens very quickly, you should be able to do all the work in 3 minutes.If you can't find this brand, you can use standard plastic glue, but try it on a small area first. To ensure that the surface forms a strong bond with the glue, treat it with chromic anhydride. It is recommended to work at room temperature; the seam will gain full strength after 6 hours.

If you don’t find anything suitable in the store, you can glue the polyethylene with epoxy resin. With this option, surfaces require careful preparation. Rub the film with fine sandpaper until the surface loses its smoothness. Degrease, coat with an oxidizing agent and dry the gluing area. Spread on both surfaces, press them firmly together and leave to harden for a day.

Advice

It is recommended to use potassium dichromate as an oxidizing agent. If you do not find this substance, treat the surfaces with a bright red solution of potassium permanganate.

Application of glue

Each brand of glue requires its own approach; all the intricacies of the work are described in the instructions for use. A good manufacturer will describe in detail how to prepare surfaces, apply the compound and make a good seam.

Before purchasing polyethylene adhesive, please read the manual carefully. There should be the following information:

- how to prepare the gluing area;

- do you need to wait some time after applying the composition;

- holding time - how long the seam should remain tightly pressed;

- drying time - after how many hours the product will acquire the required strength and be ready for use.

If the store does not have the required product, the builder is faced with the question: how to glue the polyethylene together? Masters have adapted to using other compositions.Sometimes surfaces need to be roughened or treated with chemicals. Crushed chalk or cement is added to acrylate glue, which increases the strength of the joint.

Manufacturer's recommendations vary. Sometimes surfaces need to be specially prepared. After application, some compositions need to be left for several minutes, then combined. When using other brands, the materials must be pressed firmly immediately after applying the composition. Read the instructions, everything is written there.

So, polymer film is an excellent material for the construction of greenhouses or insulation work. The polymer has one drawback: it is very difficult to choose a composition for gluing it. If you get to work, think: do you really need glue for polyethylene? Sometimes it is more convenient to use welding or double-sided tape. If you want to tackle such a difficult task as gluing polyethylene, first practice on small areas that do not require special strength and tightness. It’s impossible to learn how to do something solely from books and articles; get to work, don’t be afraid to experiment. Very little time will pass, you will get acquainted with the new material, learn its features, and very soon you will share with us your secrets of processing the capricious polymer.