Types and features of heat-resistant glue

Glue is rightfully considered the most common and convenient type of joining materials to each other. If previously adhesive compositions contained mainly natural components, today manufacturers give preference to synthetic polymers. Heat-resistant adhesive is one of the representatives of such compositions and is characterized by stable resistance to temperature changes. Using this substance, you can glue glass and metal, ceramics and brick, and the properties of the glue will remain unchanged during strong heating and sudden cooling. High-temperature adhesive is used in the construction of stoves and fireplace portals, lining heated surfaces with ceramic tiles, laying heated floors, as well as in the repair of metal and glass products.

Characteristics and properties of heat-resistant adhesive

Modern heat-resistant adhesive consists of several substances, each of which has a special purpose:

- a mixture of sand and cement;

- plasticizers (necessary to ensure high plasticity of the composition and avoid cracking of the connecting layer);

- synthetic additives that improve the heat resistance of the composition.

Often, manufacturers of heat-resistant adhesive supplement its composition with refractory clay, which ensures a reliable connection of materials and increases the resistance of the solder to temperature changes.

A good adhesive used in “hot” conditions must have the following properties:

- ability to linearly expand;

- wear resistance and moisture resistance;

- minimum stability temperature of at least 300 degrees;

- resistance not only to high but also to low temperatures;

- environmental Safety;

- versatility - the product should be equally suitable for interior and exterior work;

- good heat exchange.

Important!

If high temperature adhesive is used to join plastic surfaces, it is necessary to take into account the fact that the plastic must also be heat resistant.

What surfaces is hot melt adhesive suitable for?

Heat-resistant adhesive is suitable for joining a wide variety of materials. They can glue metal parts and bricks, wood and concrete, glass and ceramics. Regardless of the type of surfaces being glued, the connection will be strong and durable. The main thing is to thoroughly clean the surfaces of the elements to be glued.

- For brick

More recently, to build a brick stove or fireplace portal, craftsmen used refractory clay or cement as a connecting mixture. Today, when carrying out furnace work, high-temperature glue is used, which can withstand up to +1000°C. This is a very important property, since in the combustion shaft the temperature reaches enormous levels.

Important!

When choosing glue for building a stove or fireplace, it is necessary to take into account the toxicity of the composition. The lower this indicator, the fewer harmful substances will enter the surrounding space when the oven heats up.

Typically, heat-resistant adhesive contains a reinforcing component, such as fireclay fiber. This adhesive composition is best combined with fireclay bricks, from which, as a rule, furnace shafts are laid.

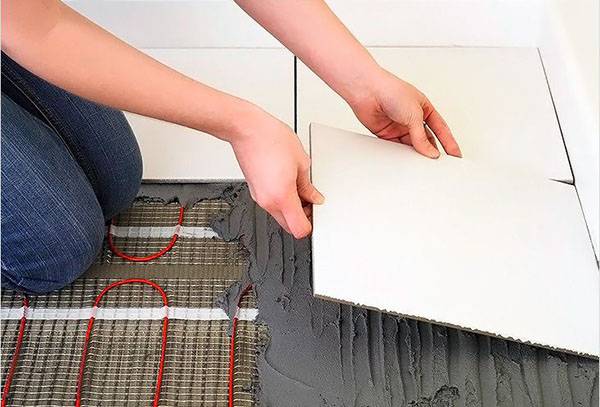

- For tiles

Experts advise using heat-resistant glue for lining stoves and fireplaces with ceramics and finishing heated floors. It is practical and convenient, has high thermophysical characteristics.

The composition of tile adhesive for high temperatures contains a mixture of sand and cement, as well as various synthetic additives that increase the adhesiveness and plasticity of the composition. This is very important, since the elements of the furnace structure, having expanded when heated, begin to narrow as they cool. If the tile adhesive does not have sufficient plasticity, the stove will become covered with cracks after a while.

- For metal

To connect metal elements, there is a special adhesive composition called “heat-resistant cold welding.” This glue contains epoxy resins, metal additives, and synthetic plasticizers. The product is available in the form of a liquid or a viscous substance similar to plasticine. If you need to glue two metal parts placed in the oven, or glue a handle to a frying pan, you need heat-resistant metal glue.

Popular brands of heat-resistant glue

Today, the shelves of hardware stores are filled with adhesives. Each manufacturer claims that their glue is the most reliable. In order not to get confused in the variety of products, you need to have an idea of the most popular high-temperature adhesives. Here are some of them.

- D-314. The adhesive produced by the Russian company Diola is intended for finishing stoves and fireplaces with ceramic tiles. The prepared mixture is elastic and shape-resistant, so the tiles do not slip and hold securely on the tiled surface.The composition can withstand heating up to +850°C, and is ready for use three days after completion of work.

- "Super fireplace." A heat-resistant composition with reinforcing fibers from the Russian manufacturer Plitonit allows you to glue ceramic, granite, and natural stone tiles to brick and concrete bases exposed to heat.

- "Hercules" GM-215. The adhesive composition is intended for the construction of fireplaces and stoves and can withstand heating up to +1200C. In addition, it is excellent for finishing heated surfaces with low-porosity ceramic tiles or glazed tiles. The glue allows finishing work to be carried out at temperatures from -10°C to +35°C.

- "The Epoxiline Moment." High-temperature adhesive is produced by the well-known company Henkel and is a two-component composition based on epoxy resin. This adhesive is used to join metal, ceramics, glass and other materials. Once cured, it forms a layer so strong that it can be drilled and polished.

Heat-resistant adhesive rightfully occupies a leading position among adhesive compositions. High adhesion, the ability to retain its properties regardless of temperature changes, strength and durability of joints, plasticity - qualities that make this adhesive indispensable in construction and in everyday life.