We didn’t know, but the electrician suggested how to correctly connect single-core and stranded wires

I want to share a method that allows you to connect single-core and stranded wires quickly, reliably and correctly. This is a real find for ordinary people who are not familiar with electrics. So, I'm telling you.

Connecting wires easily

You can put the duty tape in the back drawer: you won’t need it anymore. Instead of this:

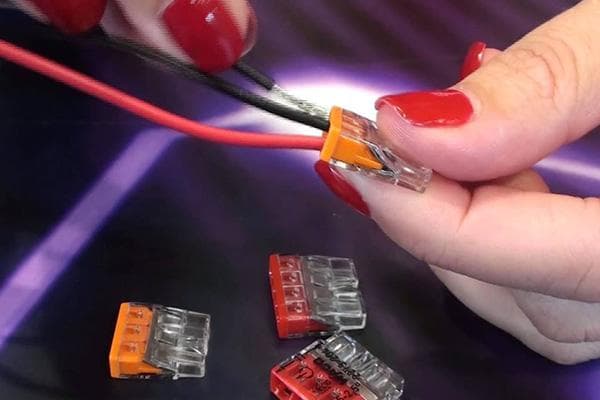

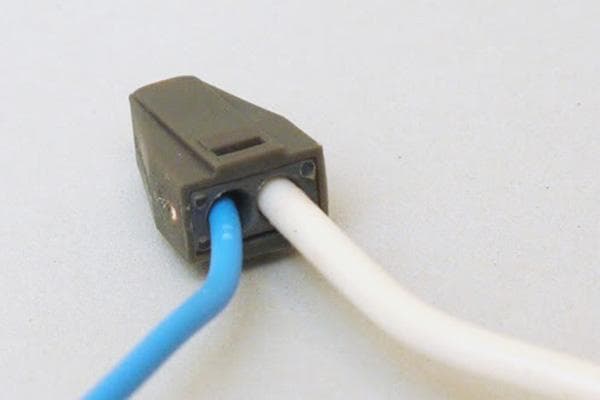

- We go to the nearest store and buy terminals (clamps). The asking price is 8–50 rubles. It is advisable to take WAGO 222 terminals with levers. As the electrician explained, they are the most reliable and easiest to use.

- We strip both wires to the depth of the terminal block, approximately 1 cm.

- We collect the strands of the stranded wire into a tight bundle and twist them slightly.

- Both conductors must be straight and clean.

- Raise the levers and insert both wires into the holes. We clamp by lowering the levers down.

Ready. With this connection method, you do not need to think about the quality of twisting and insulation. The length of the wiring remains the same. If necessary, the lever can be lifted and the wire removed - that is, the clamp is reusable.

The WAGO 222 clamp comes with 2 holes or more. It is designed for connecting single- and multi-core copper wires with a cross-sectional area of 0.08–4 mm, used in household electrical networks with voltages up to 380 V. Using the terminal block, lamps, electricity meters, garlands and much more are connected.

Types of terminal blocks

It is worth saying that terminal blocks are different:

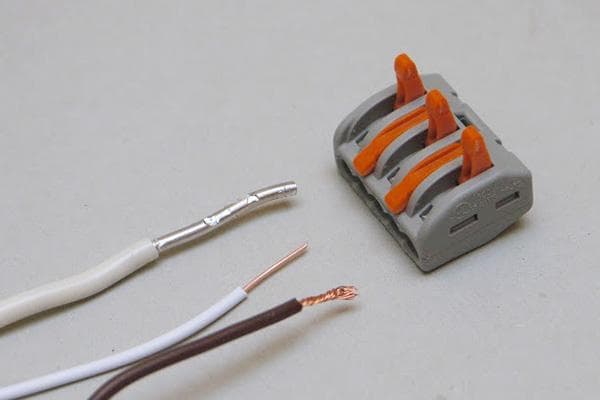

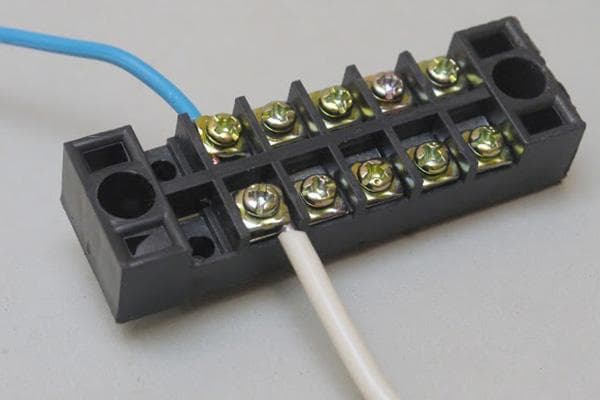

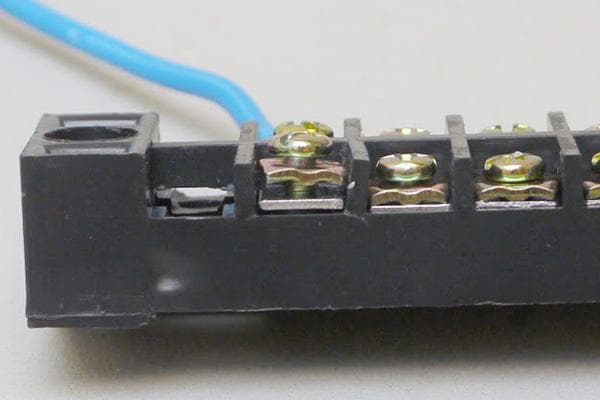

- Screw terminals in polyethylene sheath. The most common, inexpensive and structurally simple. Inside the insulating shell there is a brass sleeve with two screws - they are used to screw the wires inserted into the holes on both sides. The downside is this: screw terminals are not suitable for aluminum conductors and stranded wires. Under constant pressure from the screw, the aluminum becomes fluid and the thin strands are destroyed.

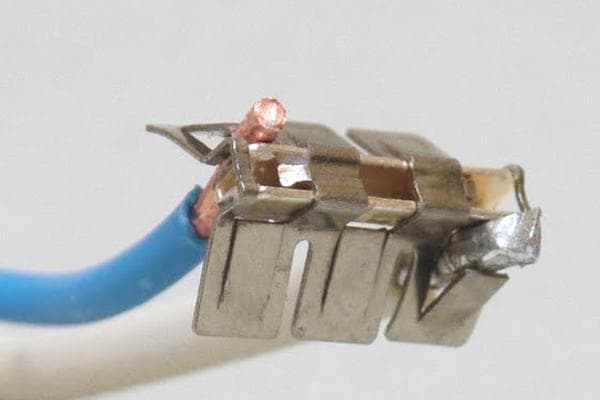

- Screw terminal blocks with metal plates. More reliable design. The wires are clamped not with screws, but with two plates with characteristic notches. Due to the increased clamping surface, these terminals are suitable for stranded wires and aluminum.

All connections with screws are tightened once a year.

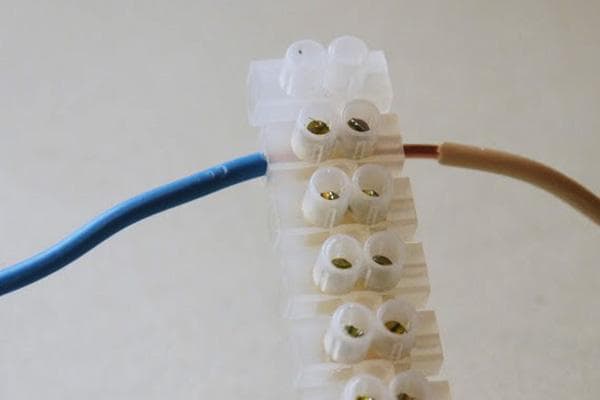

- Self-clamping express terminal blocks. No less simple design, but much more convenient. It is enough to push the wire into the hole until it stops, and it will be securely clamped. Inside there is a miniature tinned copper shank and a fixing plate. Manufacturers also often place a paste inside - a mixture of technical petroleum jelly and quartz sand. It removes the oxide film from the surface of aluminum and subsequently prevents it from forming again.

To connect an aluminum wire to a copper wire (no matter how many wires they have), you need a special terminal block with paste. The fact is that copper and aluminum form a galvanic couple. When metals interact, the destruction process starts. The resistance at the connection point increases, as a result of which the structure begins to heat up. This often leads to melting of the insulation or, even worse, sparking. The higher the current, the faster the destruction occurs.

Advantages and disadvantages of the method

Using terminals has many advantages, but it is also not without its disadvantages.For convenience, I describe them in the table:

| Terminals for connecting wires | |

|---|---|

| Minuses | pros |

| Not suitable for large gauge wires. | Affordable and versatile. You can choose a connector for almost any need. |

| Need maintenance (cannot be hidden in the wall). | Can be used for fastening single-core and stranded wires, copper and aluminum conductors, cables of various sections. |

| Not intended for high currents. | Resistant to mechanical loads and vibrations. Clamping elements prevent accidental disconnection of the wire. |

| Poor quality clamps cannot withstand the specified current. | Install quickly and easily, without special tools. The connection does not need to be further insulated. |

| Allows you to organize wiring or carry out repairs in hard-to-reach places, with a short length of wires. | |

| Easily dismantled. Some terminals can be used several times. | |

| Safe and reliable. The dielectric housing protects against current. | |

Important: in order for the connection with the terminal block to be reliable, the clamp is selected based on the characteristics of the wire - cross-sectional area, flexibility class, type of conductor. The corresponding inscriptions can be found on the clamp shell. The absence of inscriptions indicates that this is a fake. It is better not to purchase such a terminal: it may not withstand the load and melt.

What about high currents?

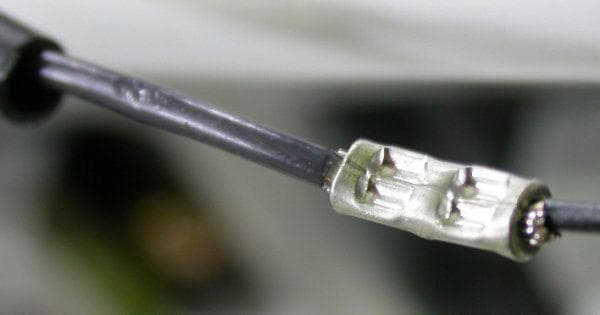

Conductors with a cross-sectional area of 35–240 mm are connected using sleeves. They come in copper-aluminium, tinned copper and aluminum. Installation is very simple - the bare wires are placed in a sleeve and then crimped. With the correct choice of sleeve size and high-quality crimping, the resistance remains the same as in a regular wire. After insulation, the wiring can be safely hidden in the wall.

There are sleeves already with insulation.

The principle of connecting single-core and stranded wires in a sleeve:

- We strip both conductors so that the bare ends reach approximately the middle of the sleeve.

- Insert into the holes on both sides.

- We crimp with special pliers.

Here we come to the main problem. The sleeve itself is relatively cheap - from 15 rubles. However, special pliers are required to crimp it. The price for them starts from 1000 rubles. You cannot replace the crimper with pliers or a hammer: the connection will be unreliable. Therefore, you will have to spend a little money or borrow pliers from a familiar electrician, as I did.

Many of us are accustomed to twisting wires together and then wrapping the connection with electrical tape. Not everyone knows that the old-fashioned method has long been outdated. New electrical installation rules prohibit its use due to unreliability, high risk of short circuits and electric shock. Today, electricians everywhere use terminal blocks, and for high currents - sleeves. We read PUE P2.1.21: “Connection, branching and terminating of wires and cables must be carried out using crimping, welding, soldering or clamping in accordance with current instructions.”

I try to connect wires the old fashioned way - I use GML and a crimping tool: crimping pliers (crimper) and for large cross-sections of conductors, a hydraulic press.

Who is bothered by the rules these days? I have a 1500 W heater with a 2x0.75 cable, and a 2200 W kettle - 2x1.0. Who knows - this is a LITTLE thing, but the manufacturers and their quality control department somehow don’t care...

1500 W is less than 7 A. The permissible continuous current for the wire is 0.75 sq. mm. — 16 A. That is, with a reserve. 2200 W is 10 A. For a wire of 1 square, the permissible current is 18 A. See PUE, table. 1.3.8, especially for carrying.

Valera, it was always different (a single wire in a pipe is 1.5mm2 19a. 2.5mm2 28a is unlimited), but in the cable there is less, 0.75 GOST 7a is not long, damn it is possible, but better than 1mm2 GOST and not any 16a is overload, is it really ours (bible) has it come to this?

Stranded wire must be crimped. Self-clamping terminals do not require maintenance, but under heavy loads they can melt, which leads to destruction. I do not recommend self-clamps when wiring a socket group.

The wire is not stranded, but stranded. I strictly solder the twists.