How to choose a good glue for furniture repair?

When choosing a good glue for furniture, you need to focus on what materials need to be glued. Often furniture parts are small pieces with a small area for fixation, therefore, the glue must provide an even and strong seam. The last choice will be color. Furniture as an interior item should be neat; there is no place for colored seams or glue smudges.

Which glue is better to choose?

An absolute requirement for glue will be strength. Furniture always experiences increased loads, and breakdowns often occur precisely in those places that are most often affected by humans: handles, finishing of end sections, legs, sides, backs.

How to choose a good furniture glue based on composition:

- Select the composition in accordance with the materials used.

- Some types of glue hold parts together, but completely corrode the base. It is better to purchase glue based on synthetic elastomers; they provide a strong seam and do not damage the surface.

- Many experts do not recommend using furniture glue, the components of which are toxic substances, for example, trichloroethane, which is dangerous to humans.

- In accordance with the advice of experienced craftsmen, good glue should have a density of 1.1 g/cm³.

- The color should match the shade of the furniture, or you can purchase colorless glue.

- Packaging rarely influences the choice, but it is more convenient if it has a dispenser or a long nozzle on the tube.Thanks to thoughtful packaging, furniture adhesive is easier to apply and distribute over the surface.

In order to fully restore the appearance or functionality of a product, furniture glue must retain its properties for a long time: not dry out or crumble when exposed to sunlight, and not melt when the temperature changes. Moisture resistance is necessary for repairing garden furniture, kitchen units or bathroom furniture.

Types and technical characteristics of adhesives

Initially, you can consider the most popular types of adhesives for joining parts made of wood, plywood, MDF or chipboard. The vast majority of modern furniture is made from these materials.

What experienced carpenters recommend using:

- PVA in all its varieties - D2, D3, plasticizers and type D4 for a narrow range of works where absolute strength is needed;

- furniture adhesive based on polyurethane or PUR;

- epoxy (one-, two-component);

- carpentry (often called "animal");

- contact;

- hot melt adhesive.

Casein glue is used less often for wood, the disadvantage of the composition is low resistance to moisture. Experienced craftsmen often advise using cyanoacrylate types of glue.

Description of popular types

In the broadest sense of the word, all the types of adhesives described above are intended for working with wood, and accordingly, are also suitable for furniture, but there is a difference between them.

PVA based glue supplemented with various components, thanks to which the composition acquires certain properties: plasticity, heat resistance, moisture resistance. Thus, type PVA-1 is suitable for interior work and for gluing furniture, but quickly dissolves with water.PVA-2 is relatively resistant to moisture, but over time the seam will deteriorate from water, so here moisture resistance is rather an additional property.

Almost all types of PVA glue leave marks on workpieces; extreme caution should be exercised when working.

PUR – polyurethane-based adhesive provides a high-strength seam that is resistant to temperature and humidity. The composition can be used for both interior and exterior work, for example, for repairing street furniture. Curing occurs due to exposure to moisture from the air, but for rapid setting, the creation of an artificial damp mist is allowed.

Epoxy resin adhesive glues wood very well. It is available for sale in different forms: two-component (base + hardener) and one-component (acquires adhesive properties when mixed with water). If the product is made from materials that are not resistant to water, you should choose a two-component mixture; in other cases, a regular one-component epoxy adhesive is suitable.

"Contact" for wood or furniture is a quick-drying furniture adhesive that contains solvents (volatile substances). Suitable for restoration and repair work on furniture made of wood and its derivatives.

Wood glue has a wide range of applications. The adhesive mixture provides a strong, durable seam, but the preparation process is quite long: the granules are dissolved in water, then boiled in a special glue container.

Hot melt adhesive – this term refers to two completely different types of glue: polyurethane rods and high-temperature resistant glue. Glue sticks are melted using a glue gun; the composition is universal and suitable for various types of work.High-temperature adhesive is used to join parts that are regularly exposed to elevated temperatures (furniture near the fireplace, oven, stove).

Subtleties of application

Wooden blanks are less capricious; the fibers actively absorb resin-based compounds and liquid or semi-liquid glue. A furniture façade made of MDF is durable, pressed cardboard; it will swell due to humidity, and when it dries, it will deform and “shrink.” Veneer has similar properties; like MDF, it is glued with plastic compounds: PUR, plastic PVA (for example, from Elmers or Titebond).

It is best to glue plywood parts with epoxy glue; it is quite strong, but in some cases it is difficult to use due to its high density. An alternative is Moment glue or a rubber-based composition. They provide a strong seam that will withstand regular vibrations.

For chipboard, contact adhesive or PVA is used (using a press or clamps), but with laminated chipboard it will be more difficult. Parts made of laminated chipboard need to be sanded and glued with the same contact adhesive, however, not every varnished coating can be sanded. If the coating cannot be removed, you can use PUR hot melt adhesive.

How to use glue correctly?

The technology for gluing furniture is based on the general rules for joining wood blanks:

- The surface is cleaned of any contaminants and thoroughly dried (for using PUR, humidity, on the contrary, will speed up the gluing process).

- The adhesive layer should not exceed 5 mm, but different manufacturers have different recommendations. The optimal seam thickness is 3 mm.

- Consider the color of the glue - the white or yellow composition will be visible under a layer of varnish or stain; for decorative work it is better to purchase transparent glue.

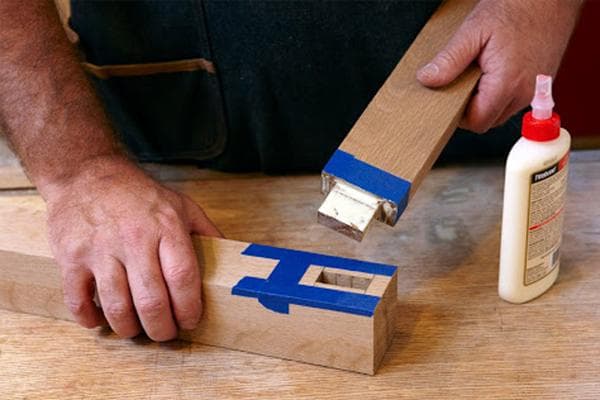

- The composition is applied to both sides with a wave, unless otherwise indicated in the instructions, leveled with a spatula or brush and compressed tightly (placed under a press, tightened with self-tapping screws, clamps).

- Most often, the time for complete polymerization/hardening is a day; contact adhesive dries faster - from 5 seconds to 15 minutes.

The best glue manufacturers

Among the masses of various manufacturers, companies that specialize in the production of glue are especially popular:

- "Moment",

- Tytan,

- Soudal,

- Elmers,

- Titebond,

- Bostik.

The products of these companies include hundreds of different types of furniture glue, differing in composition, properties, packaging and application method. However, for a small amount of work or for gluing technical elements of furniture that are not visible to the eye, PVA or epoxy glue from a domestic manufacturer - Kapral, "Triol" - is perfect.

How can you glue a wooden chair together?

The peculiarity of this product is its small application area: legs, handles or back parts are made from narrow, thin blanks. The main factors in choosing an adhesive will be high strength and semi-liquid consistency.

It is not recommended to use plastic types of glue for gluing chairs. The dense composition is difficult to distribute over a small area.

To glue a chair, it is better to choose one of the following compositions:

- polyurethane glue, such as Titebond;

- “Moment Stolyar” is a high-strength composition that is easily washed off with water;

- Kleiberit PUR is a polyurethane furniture adhesive with excellent adhesion that withstands humidity, dampness, high and unstable temperatures, and exposure to ultraviolet radiation.

According to experienced carpenters, the most common mistake in repairing and restoring furniture is neglecting the recommendations of the glue manufacturer and using the composition for other purposes. When choosing furniture glue, it is important to consider two key factors: the characteristics of the product itself and the external operating conditions.