Why doesn't the washing machine drain water and what to do in this case?

Content:

A modern person can no longer do without an automatic washing machine. A household appliance saves energy and time, which can be devoted to communicating with loved ones. But then a problem happened - the washing machine does not drain the water! This is a frequent breakdown, which, nevertheless, confuses and spoils the mood. There is no need to panic - based on the signs of a malfunction, you should try to identify the possible cause and try to fix it yourself.

Why is there no water draining?

Draining contaminated water after the main stage of washing or rinsing proceeds in this way: water from the drum through the outlet pipe under the action of the exhaust pump impeller enters the outlet filter (the part is needed to prevent large fragments that appeared during the washing process from entering the hose - torn buttons, coins from pockets). After passing through the filter, the water flows through the drain hose into the sewer. The drain pump is controlled by an electronic board.

| The washing machine does not drain water | ||

|---|---|---|

| The pump is running, but the water is not draining | The pump runs intermittently | The pump does not work, the water does not drain |

| Tank pipe is clogged Drain hose clogged Filter clogged Broken pump impeller | Program failure on board Poor contact of wires from the board to the pump | Pump motor faulty Damaged pump power wires |

Thus, water may not drain due to malfunction of various elements:

- drain hose;

- exhaust filter:

- pump impellers;

- pump motor;

- exhaust pipe.

- electronic board.

The causes of failure can manifest themselves in different ways, for example:

- the draining stage is slower than usual, and washing programs may fail;

- the program stops execution at the moment of draining;

- the malfunction occurs periodically - with some washes it ends successfully;

- When the pump is running, the water does not drain.

First aid for the car

Some malfunctions in which the machine does not drain water can be identified and eliminated without opening the case.

If the washing machine is under warranty, without loss of obligations of the manufacturer and the seller, you are only allowed to check the drain hose and clean the drain filter. Opening the device case will leave you without free repairs for the entire warranty period.

Control board failure

In the event that the washing modes are not performed correctly, the processes stop at any stage, or the modes change each other incorrectly, a possible reason is a malfunction of the electronic board. A failure, as a rule, occurs due to voltage drops in the network that occur after turning on the washing mode. Such differences are not uncommon in old houses.

The machine is disconnected from the network by removing the plug from the socket and left for 10-15 seconds without power connected. During this time, the capacitors in the electrical circuit and on the control board will discharge.The program will be “reset” and you can restart the second wash. The device is plugged in and they try to start the wash. If these actions do not produce results, they continue to look for reasons.

Before testing, you must drain the water manually.

How to drain water from a washing machine?

How to drain the remaining water from the washing machine must be described in the operating instructions.

The filter and emergency water drain tube are usually located at the bottom of the front panel of the washing machine. The installation location can be disguised with a hinged cover. To access the filter and emergency drain, open the cover using a flat screwdriver or the tip of a knife. Some devices do not have a cover and access is possible directly from the front panel.

The design of the lids and the mechanism for opening them differ on different models of household appliances. To avoid damage, do not use excessive physical force. How to open the lid on a washing machine is specified in the operating instructions.

There may be a small piece of hose under the lid to drain the water. In other models, a tube of suitable diameter is connected to a special fitting on the filter housing. It is necessary to clarify information about emergency drainage rules in the product instructions.

Substituting a container with low sides, drain the liquid from the tank.

After the water has been drained, a small amount of it remains in the hoses; to eliminate its leakage, you must use a dry rag.

Checking the drain hose

The following common causes of malfunction are:

- clogged drain hose;

- kinked or kinked hose.

Kinks are eliminated by straightening the tube.

Remove the blockage by disconnecting the hose and rinsing it with a stream of water. If this does not help, use a piece of flexible elastic wire for cleaning. You must act carefully so as not to damage the walls of the hose.

You can always pick up a spare hose in the store. To do this, you need to take a piece of the old one with you.

What to do if a fault is not identified? Continue searching.

Filter clogged

Usually the filter mesh is separated from the body by rotating counterclockwise, but in order to prevent damage, check the information in the instructions for the washing machine.

For ease of removal, you can use pliers. Having removed the filter element, they evaluate whether blockage is possible from the debris present there, clean it and install the filter in place.

It is necessary to check the condition of the filter without waiting for breakdowns. Timely removal of the blockage will prevent an unpleasant odor from appearing from the car.

In some models, through a hole in the filter housing, you can check the condition of the pump impeller.

Partial disassembly checks

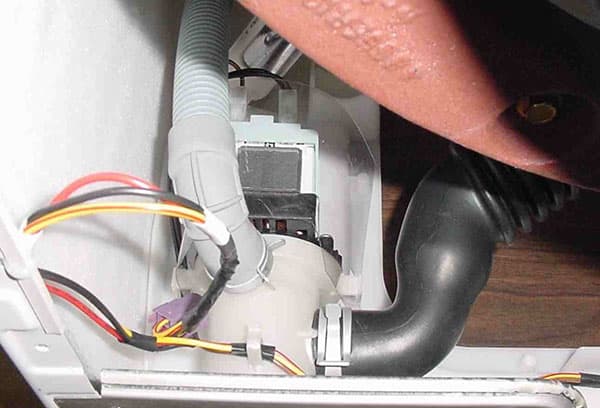

By removing the back cover, you can identify problems with the pump and electrical wiring of the washing machine.

Checking the pump power wires

The integrity of the wires is checked with a multimeter, setting the resistance measurement limit to the “Ohm” position. The wires must be disconnected from the board and pump. Indications other than “0” indicate the need to replace or restore contacts.

Another way is to use a screwdriver with a resistance test function. In this case, the indicator should light up.

“Jumps” in the device readings when the wires are bent indicate internal breaks.In this case, vibration during washing causes the wires to close or open, causing interruptions in the operation of the pump.

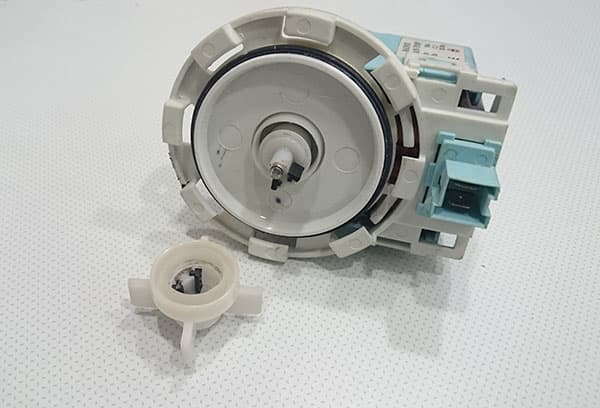

Checking the impeller

For Indesit, Bosch, LG and other washing machines, the impeller unit is made in such a way that it can be changed by disconnecting it from the electric motor.

After removing the pump from the washing machine, use a screwdriver to unscrew the mounting screws and disconnect the pump parts.

The shaft blades must be in good condition. The absence or breakage of one of the blades entails the replacement of the entire part.

The pump shaft must rotate freely in the bearing. If necessary, replace the bearing if the design allows this.

The cause of pump jamming can be pieces of thread, pieces of fabric, or hair wound around the pump shaft. In this case, cleaning and performance testing are carried out.

Checking the pump motor

A pump motor malfunction is usually displayed as an error code on the control unit screen. You can check the motor yourself with a multimeter.

Before taking measurements, consider whether you have the skills to take electrical measurements and whether you can correctly identify the results obtained.

To do this, disconnect the electrical wires. A test is carried out using a multimeter in resistance measurement mode. If the device shows “1”, this is evidence of a break in the motor windings. “0” indicates a short circuit. In both cases, the engine must be replaced. Correct operation is indicated by instrument readings that differ from “0” and “1” (or “∞”). It all depends on the selected measurement limit, the performance of the multimeter and its batteries.

Checking the pump of a washing machine if you have the skills to handle tools and electrical measuring instruments is not very difficult.

Fixing minor problems yourself will help save your family budget. Repairs when the machine is under warranty or in case of complex faults that could not be reliably determined are best entrusted to employees of specialized organizations.