Sharpening the hair clipper

With the invention and further improvement of shaving machines, the crowds of barbershop visitors thinned out significantly. The men quickly realized that sharpening hair clippers is a simple matter. This, like the haircut itself, can be done at home. The work is quite simple, but the preparation and implementation of the necessary procedures must be competent and of high quality.

When do you need to sharpen machine blades?

Ideally, the cutting parts should be cleaned and lubricated after each haircut and shave, but most often you are simply too lazy to disassemble the body and tinker with the blades.

Typically, the sharpness of the knives is enough for 10–15 haircuts, after which the following problems appear:

- hair straightening becomes a complex and time-consuming procedure;

- During a haircut, an unpleasant sensation of “tugging” of the hair appears;

- after the procedure, the skin on the head is irritated, there may even be small cuts;

- The engine of the machine begins to hum strongly due to the increased load.

Since it is always easier to cut wet hair, very often the knives come into contact with moisture. As a result, dust sticks to the blades faster and the metal parts quickly rust, especially if they are uncoated. This can be easily corrected by proper cleaning and sharpening of the blades.

Properly preparing for sharpening

First of all, you need to prepare the equipment that will be needed for sharpening. In general, the set of tools depends on the sharpening method.You may need:

- professional sharpening set;

- sandpaper;

- grinding stone;

- cloth or paper napkin;

- water;

- silicone grease, immersion or machine oil (in no case vegetable oil);

- durable glass or mirror as a base.

Cleaning the blades

Cleaning knives is an important aspect of the procedure. For self-sharpening razors, it is enough to remove hairs and rust from the knives and lubricate the cutting edge - and the quality of the haircut will noticeably improve.

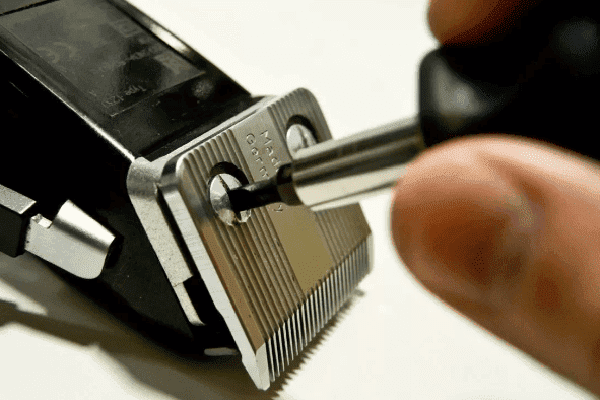

- The knife block must be separated from the main body, unscrew the mounting screws, and separate the blades.

- Using a cloth (you can use a soft brush), carefully clean the metal surfaces of the knives.

- To remove rust, the blades are immersed in a special solution (you can use a 9% acetic acid solution) for several minutes.

Then, after drying, you can begin sharpening.

Using a professional kit

For such sharpening you need to have basic skills in handling tools.

- All parts of the sharpening tool must be thoroughly cleaned with a brush or sponge.

- Treat the surface of the disc with lubricant, and the oil must be thoroughly rubbed over the entire area.

- Then apply a thin layer of abrasive powder evenly to the surface and rub it in.

- The blades must be installed on a magnetic laser holder, turn on the machine and sharpen the knives with even movements from the periphery to the central area of the rotating disk.

- After sharpening, carefully remove grains of powder, rinse the blades and dry.

The machine is assembled in a strict sequence opposite to disassembly.

Easier ways

You can use a good old sanding block.To do this, you need to firmly fix the blades with your fingers and move them along the surface of the stone in the longitudinal and transverse directions. Movements should be smooth, without pressure. When the knives become sharp, they will acquire a characteristic shine.

You can also use finely-coated sanding paper (P 600 is sufficient):

- Place the sandpaper on the glass and moisten it with water to form an abrasive mixture.

- Fix the blades on a magnet and move them along the sandpaper, as if drawing “figure eights”.

- After the procedure, rinse the knives thoroughly under a powerful stream of water and dry them.

- For grouting, use sandpaper with grit P 2000 and sharpen the blades in the same way.

After final assembly, you can drop a little silicone grease or oil on the teeth of the machine and turn it on so that the lubricant is completely distributed between the rubbing parts of the machine. Treat the outer parts of the cutting surfaces in contact with the skin with medical alcohol: observing asepsis and antisepsis is very important.

If, after all the procedures (provided they are performed correctly), the blades still “jerk” and cut poorly, then the problem is the quality of the steel itself. In this case, you will have to replace the knives in specialized stores, which will be very difficult to do.

Repair and clean only yourself

Yes. Well, it's very simple! Why laugh at ordinary people. I know very well that such procedures are not easy to carry out; they require skills. That's why the article interested me. I thought they came up with something new.