Akfix glue: instructions for use, composition, varieties

Content:

New materials make it possible to speed up construction and repair work. Akfix glue is suitable for quickly gluing various surfaces. Several compositions have been developed, taking into account the operating conditions of the facility and the type of products being processed.

Description and scope of application

The quick connection kit consists of two components: a 50mm canister of adhesive polymer and a 200ml activating aerosol.

The product is intended for express gluing:

- elements made of chipboard, MDF, solid wood;

- PVC panels;

- parts in the automotive and electrical industries;

- rubber, plastic, polyurethane surfaces;

- billets made of aluminum, fiberglass, hydrocarbon steel;

- stone

Akfix is used for repairing displays and household appliance accessories; it firmly adheres to any materials except Teflon, ABS, polyethylene, and propylene. The set is used in the manufacture of furniture, door frames, installation of aluminum edging on containers, vehicles, and windows.

Composition and main properties

The two-component adhesive formulation includes ingredients that ensure reliable connection of surfaces, equipment parts, and components.The popularity of the substance is due to its excellent characteristics and the possibility of use by professionals and ordinary consumers.

"Akfix 705"

Cyanoacrylate-based adhesive does not contain solvents; additional application of an astringent gel with an activator (isopropanol with additives) is required for gluing. Akfix 705 sets instantly, the chemical process is completed in 3-4 seconds. The gel remains strong and transparent after application.

"Akfix 610"

Superglue is made on the basis of polyurethane, is economically used, and provides high quality mating. The composition is resistant to temperature fluctuations, moisture, and chemical influences. The substance is transparent, has good viscosity, and is environmentally friendly. Liquid nails 610 do not drip, which makes it possible to work with vertical and inverted surfaces.

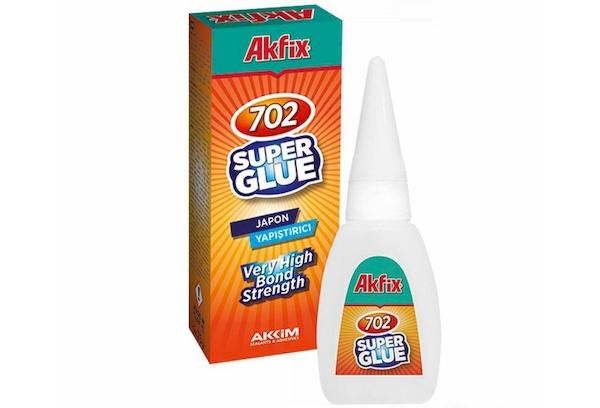

"Akfix 702"

The one-component adhesive is made on the basis of cyanoacrylate and polymerizes quickly. Before treatment, surfaces are cleaned, degreased, and dried. The composition of 702 does not contain solvents; the chemical reaction is carried out due to atmospheric moisture. Operating temperature range – +5-+40 °C.

"Akfix 710"

Two-component adhesive consisting of high-viscosity cyanoacrylate and an activator additive. Purpose – combination of stones of natural and decorative origin. Product 710 is characterized by gluing speed (2-4 seconds) and increased adhesion. Suitable for processing vertical and porous objects.

Instructions for use

Before applying Akfix superglue, prepare the surfaces to be treated and thoroughly clean them of dust, grease, and dirt. If there are rough parts, this is not critical; it does not affect the quality of the coupling.

Instructions for use:

- Glue is applied to one element, and an activator is applied to the other side.

- The spray is sprayed with a thin stream from a distance of 25-30 cm.

- An alternative is to apply the activator directly to the gel.

- After processing, the surfaces are immediately pressed.

- The product is ready for use in 6-12 hours, depending on the dimensions.

One-component composition 610 is used to treat one side of the mating parts, pressing the parts together with force. The thickness of the applied layer is 0.2 mm, the excess is removed immediately, without allowing it to harden, using white spirit or acetone.

Precautionary measures

When using polyurethane-based Akfix glue, adhere to the following precautions:

- ventilate the room;

- protect your eyes with glasses;

- do not allow the substance to come into contact with the skin;

- Avoid inhaling adhesive vapors.

Additional tips and tricks

The recommended humidity when working with Akfix glue is 50-75%; increased dry air impairs adhesion, increasing the setting time. Excess moisture promotes polymerization of the composition, but weakens the bond strength.

The glue adheres well to parts made of base metals. When processing rubber, it is advisable to make a cut on both parts of the workpiece, followed by a soft connection; the coupling is instantaneous. For preliminary cleaning of serviced surfaces, use sandpaper, soap solution or steam treatment.