How to dissolve and prepare glue and varnish from foam plastic

Content:

- Types of foam suitable for preparing glue and varnish

- Using plastic glue at home

- All about homemade glue from polystyrene foam and gasoline

- Homemade glue from polystyrene foam and acetone: features and application

- Features of preparing varnish for concrete coatings made of polystyrene foam and xylene

- What you need to know when making foam and solvent adhesive

- Step-by-step guide to making foam glue

- How to use homemade glue

- Step-by-step instructions for preparing varnish from polystyrene foam gasoline and xylene

- Basic rules and safety measures

Households often need glue for repair work. Buying glue and varnish is not always a good price-quality ratio. Little secrets will help you create both products with your own hands.

Types of foam suitable for preparing glue and varnish

It is quite easy to dissolve polystyrene foam, since it is characterized by low resistance to many organic solvents. However, there are types of foam from which it is difficult to prepare glue or varnish.

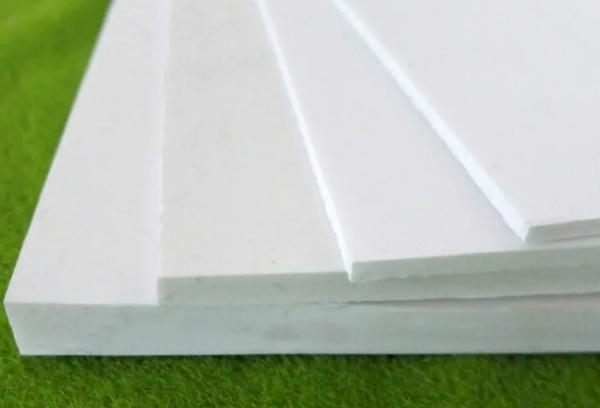

Types of expanded polystyrene:

- Granular or pressless foam. This type of foam is quite fragile in structure and easily crumbles and breaks.Ideal for making glue and varnish, as it dissolves quite quickly under the influence of any organic solvents.

- Pressed foam. This type has a dense structure; it is possible to crumble such material, but it is difficult. Under the influence of solvents, this type of foam partially dissolves, as a result of which the composition is heterogeneous and quickly hardens. It is used extremely rarely for the preparation of varnish and glue.

- Extruded foam. This type is distinguished by a strong, dense structure with a smooth surface. This type of polystyrene foam is considered the least suitable for making varnish and glue.

For the preparation of glue and varnish, sheets of thermal insulating foam, polystyrene from packaging from household appliances, and granulated foam balls are widely used.

To prepare glue and varnish, it is recommended to use polystyrene foam without contamination with paint, primer, as well as without chemical and construction impurities and specific odors.

Using plastic glue at home

Despite its homemade composition, foam glue has good adhesion to almost any surface and does not collapse under the influence of low and high temperatures. The shelf life of homemade glue from the moment of manufacture is approximately 20-30 minutes. However, in places of gluing, the adhesive retains its properties for more than 2 years.

Homemade glue is used for the following types of repair and installation work:

- sealing and sealing joints, cracks, crevices;

- gluing household products and furniture fittings;

- fixing plinths and cornices;

- gluing roofing materials and sealing tile and slate roofs;

- fixing squeaky floorboards and sealing gaps between them;

- connections of insulating panels and their joints for thermal insulation of foundations, plinths, loggias, balconies.

Foam adhesive is ideal for joining and gluing hard materials. It is not recommended to use homemade glue when working with rubber or leather materials, as the adhesive quickly hardens and deforms the structure of such products.

All about homemade glue from polystyrene foam and gasoline

Polystyrene foam dissolves quite easily in gasoline. To prepare the glue, choose pure gasoline without fuel impurities.

The best types of gasoline include:

- Vietnamese gasoline (consists of 50% gasoline and 50% acetone);

- gasoline solvent “Galosha”, or “Galosha” (a type of nefras);

- dearomatized gasoline "Nefras";

- gasoline solvent "Shellsol";

- gasoline A-95.

It is recommended to use ready-made homemade glue based on polystyrene foam and gasoline for 20-30 minutes. Otherwise, the structure of the adhesive and the quality of adhesion to the surface will be significantly reduced.

It is not recommended to use biogasoline or leaded gasoline, as such mixtures contain large amounts of fuel alcohol. In the process of preparing glue based on such gasoline, there is a high percentage of evaporation of toxic fuel substances, which can greatly harm health.

Use of gasoline-based foam glue in the household

Gasoline-based adhesive is used primarily for external installation work. Ideal for gluing paper, wood and plastic materials. However, the application and reliability of the adhesion depends on the consistency of the resulting mixture.

Too liquid adhesive mass is used as a varnish, which is used to treat wooden and concrete surfaces. A thicker consistency is used as glue.

For waterproofing, prepare a viscous and uniform glue consistency. This adhesive is used to waterproof and protect the outer walls of a building and basement wall lines from moisture. With this composition you can glue rolled roofing waterproofing material (roofing felt and roofing felt) and attach flexible tiles to a continuous homemade adhesive layer. You can seal large cracks and holes on the facade of the building and even block holes in the sewage system on your personal plot.

Homemade glue from polystyrene foam and acetone: features and application

Acetone instantly brings the foam to a liquid state. Acetone is more effective as a solvent than gasoline. Acetone glue is much softer, more viscous and viscous.

This glue is widely used for the following types of work:

- gluing cardboard products;

- connections and fastenings of gypsum products;

- connections and fastenings of plastic and wood materials (plinths, cornices, wooden slats, small wooden products, fittings);

- processing and gluing joints;

- filling seams, cracks, depressions;

- installation of plank floorboards;

- elimination of defects on chipboard and plywood.

The main advantage of acetone is its ability to dissolve foam 100%. This glue can be used as a substitute for such expensive adhesives as casein and carpentry.

Features of preparing varnish for concrete coatings made of polystyrene foam and xylene

You can make varnish at home from polystyrene foam and xylene.The foam dissolves in xylene in a matter of seconds, leaving no lumps. Xylene dissolves foam better than gasoline and acetone.

Xylene-based varnish has good coverage, high transparency and fast drying. They coat wooden products with homemade varnish and also use them to protect against dampness and improve the appearance of concrete surfaces. Such surfaces include concrete floors in the garage, on open verandas and balconies.

Before covering, it is necessary to clean the floors from small debris and dust. There are two ways to coat a concrete floor depending on the consistency of the varnish:

- Thick and more viscous varnish is applied in a thin layer to the concrete surface using a spatula. This option of applying varnish is labor-intensive, however, it allows you to apply the varnish in a thin and uniform layer.

- A varnish that is fluid and more flexible in texture is applied to concrete and wooden surfaces. The varnish is well absorbed, however, to obtain a pronounced glossy effect, the product must be applied in 2-3 layers.

What you need to know when making foam and solvent adhesive

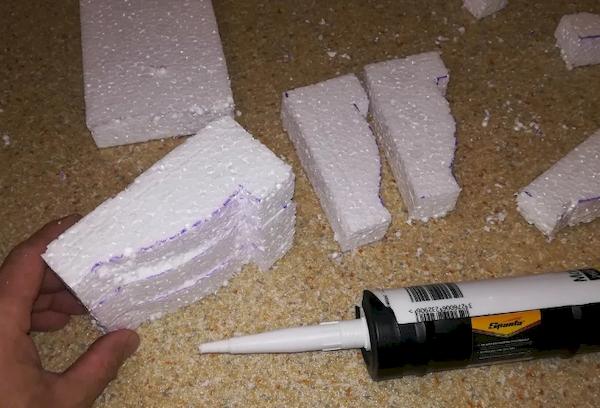

When making adhesive from foam plastic and solvent, it is important to maintain the correct proportions, since the solvent has a high level of absorption of gas-filled materials. To prepare the adhesive, you need to mix the foam and solvent in a ratio of 1:4. This consistency is ideal not only for gluing small wooden and plastic materials, but will also serve as a good sealant for cracks and crevices.

Solvents are low cost, less toxic and have a low chemical odor.

There are main types of solvents suitable for making glue and varnish from foam plastic:

- solvent 650;

- solvent 647;

- solvent 646;

- solvent R-4;

- solvent R-12.

Experts warn that the qualities and properties of the above types of solvents may differ depending on the manufacturer. When purchasing, you need to pay attention to the composition of the solvent. The solvent must contain high-boiling elements such as methylpyrrolidone, DMF, DMSO and propylene carbonate.

Step-by-step guide to making foam glue

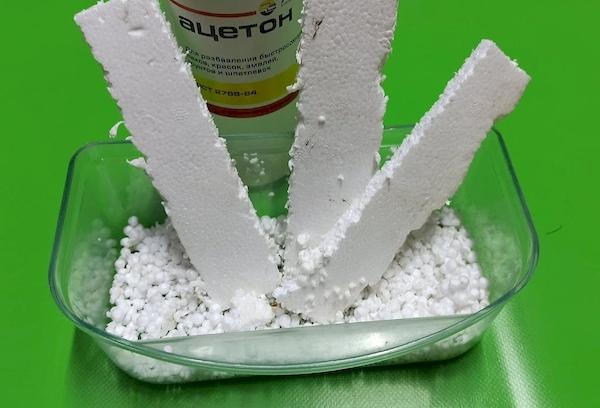

To prepare the glue, you will need a large amount of foam, since most of the volume of foamed foam consists of gas, which evaporates strongly under the influence of organic solvents.

Polystyrene foam is 95% gas and only 5% foamed polymer. Styrofoam uses about four times more than solvent.

| Illustration | Description of action |

| To prepare the glue, you need two main ingredients: polystyrene foam and any organic solvent (gasoline, acetone, thinner, xylene) | |

|

To prepare foam glue you will need pressless foam, gasoline solvent, a glass container, and a spoon. |

|

Gasoline is poured into a glass container. The amount of solvent depends on the mass of the adhesive. |

|

The foam is placed in a container with solvent and lightly pressed down on top with your hand. As soon as the foam comes into contact with the solvent, a characteristic hissing and foaming will appear due to the evaporation of gas. |

|

Depending on the consistency, foam or solvent is added. The adhesive solution should have a similar consistency to sour cream. |

|

If the mixture is too thick and lumpy, it is recommended to add a little solvent. To get rid of gas bubbles, the mixture must be thoroughly mixed with a spoon. |

|

If the mixture has the desired consistency, but has lumps, it must be rubbed through a sieve immediately after preparation to obtain a homogeneous mass. |

|

The resulting adhesive can be used as soon as the adhesive has stopped emitting gas. |

How to use homemade glue

There are two main ways to use homemade glue. The first method is used if the glue was prepared for gluing small wooden and plastic materials.

The second method is for filling holes, seams, cracks and crevices.

- Before applying the glue, the surface of the materials is treated with acetone or solvent for stronger adhesion. The glue is applied in a thin layer using a brush. After application, excess glue is removed with a soft rag.

- Shallow seams and cracks are filled using a special construction syringe. Excess glue is removed with a plastic spatula. Large holes and depressions are filled in several stages. The step-by-step filling method allows the recesses to be completely sealed, without the formation of voids, and to dry well.

The main disadvantages and advantages of homemade glue

Despite the ease of preparing homemade glue from fairly simple, accessible and cheap materials, foam glue has several disadvantages.

These disadvantages include:

- limited validity period of freshly prepared glue;

- low adhesion and strength of the adhesive seam;

- gluing materials requires 3 times more homemade glue compared to polyurethane glue;

- the layer of glue in the places where two parts are glued dries for at least a day;

- For better adhesion to a smooth surface, pre-treatment of the surface with acetone is required.

Step-by-step instructions for preparing varnish from polystyrene foam gasoline and xylene

You can obtain high-quality and inexpensive varnish for concrete coatings using polystyrene foam, gasoline and xylene. To create a more decorative look for floors, the varnish can be tinted with color.

The following step-by-step instructions will help you prepare colored varnish with your own hands:

| Illustration | Description of action |

|

To prepare the varnish, you need to prepare polystyrene foam, pure gasoline, xylene, and color in advance. |

|

Stage 1: Dissolve pieces of polystyrene foam in gasoline in a ratio of 1:5. To obtain a homogeneous mass, pieces of foam plastic should be loaded into the container gradually. The mixture should be stirred constantly until the gas evaporates completely. |

|

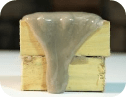

The finished mixture should resemble thick sour cream in consistency and chewing gum in viscosity. |

|

Stage 2: Dilute the finished mixture with xylene in a ratio of 3 parts of the finished mixture to 1 part of xylene. The result is a viscous liquid, similar in structure to industrial varnish. |

|

Stage 3: to tint the varnish, use any universal color for tinting putty or paint. The color should be stirred well and let sit for 10-15 minutes. |

|

Colored varnish is applied with a paint brush to a dust-free surface. The surface is painted in one layer. |

Foam varnish is applied in a thin layer for quick adhesion to the surface. It is best to work with the coating in warm weather; the optimal air temperature for work is 18-20℃.

Basic rules and safety measures

The use of any type of solvent poses a safety hazard, since acetone, gasoline and other types of solvents are flammable materials and are highly flammable, and therefore all necessary precautions must be taken.

Flammable and chemical materials can cause a severe allergic reaction. Therefore, for the first time it is recommended to prepare a small amount of the product, this will allow you to check the body’s reaction to volatile substances that evaporate when working with solvents.

When preparing glue or varnish, it is necessary to have a fan turned on and protective gloves, since chemicals in the process of oxidation and dissolution release specific toxic substances that can provoke not only an allergic reaction, but also poisoning.

Basic recommendations: carry out work outdoors, use gloves when working, do not use matches, lighters or other means used to create an open flame.