A pipe is leaking - what can you do to avoid calling a plumber?

The appearance of rusty streaks and puddles are sure signs that a pipe is leaking. What to do in such a situation? First of all, calm down and act consistently. In most cases, you can deal with a leak yourself. The easiest way to eliminate it is mechanical. You will need a piece of rubber (from a hose, bicycle inner tube, rubber gloves) and wire or a commercial clamp.

How to quickly fix a leak?

A leaking water pipe can cause flooding of your home and damage to your property and that of your neighbors. You need to act quickly in such a situation:

- If possible, turn off the water supply to the system (area being repaired).

- Clear the repair area. Move the furniture aside and put down dry rags.

- Prepare tools: pliers, screwdriver, flexible wire or clamps, thin rubber.

- Cut out the desired piece of rubber sheet. It should cover the leak site with a margin of 2–3 cm in each direction.

- Press the pad firmly onto the fistula (crack). If it is too thin, wrap it in 2-3 layers.

- Holding the overlay with your hand, place the wire on top. Tighten it by making tight turns with pliers.

- Cut off the excess wire, leaving 5mm ends.

- Bend them so they don't protrude.

Pipes leak especially often in houses with old plumbing. In bathrooms and toilets where humidity levels are high, metal is at high risk of corrosion. Salts and various impurities in the water contribute.To prevent leaks, anti-corrosion paints and primers are used. Some of them can be applied directly to the rust.

If water comes out of the fistula under pressure, that is, in fact pipe burst, find something to fill the hole with. The easiest way is to block the flow with a chopper. Sharpen the end of the piece of wood to fit into the hole. Lightly tap the chop with a hammer.

Clamp to help

Difficulties often arise when winding wire. In order for the structure to be sealed and withstand pressure, it must be pressed very tightly against the rubber. But if you apply too much force, the wire breaks off or cuts through the pad.

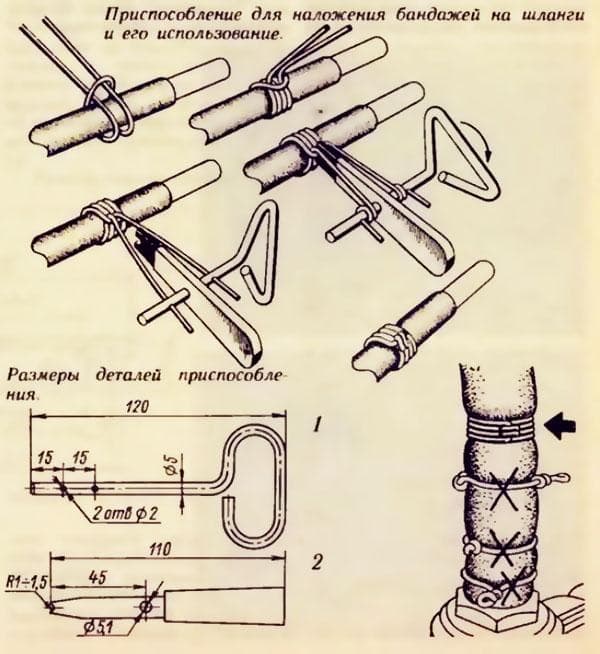

To tighten the wire, many craftsmen use a homemade tool - a clamp. The device is easy to make at home. With it, the wire tightens the elastic evenly along the entire length.

How to do it yourself?

The clamp is a simple design. Usually craftsmen make it from what is at hand: a steel sheet, a piece of pipe, a stud and nut, a door hinge, a furniture screw, etc.

Here is just a small part of the device options:

- A good clamp with a handle:

- DIY clamp in 30 minutes:

- Door hinge clamp:

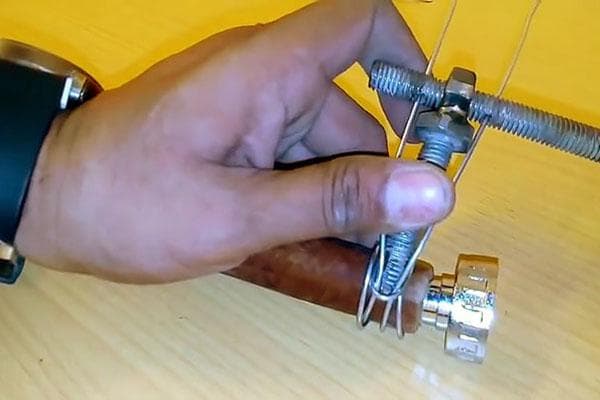

We suggest making the simplest clamp from 2 bolts (long and short), a stud, 2 nuts and electrical tape:

- We sharpen the end of the short bolt shaft to a blunt wedge.

- In the middle we make a shallow slot 3 mm wide.

- We weld a nut placed in a vertical position to the bolt head.

- In the same way, weld the second nut to the long bolt.

- We screw the pin all the way into the middle and wrap it with electrical tape to secure it.

- We retreat 2 cm from the edge of the long bolt and drill a hole with a diameter of 2.5-3 mm.

- At a distance of 2 cm, drill another similar hole.

- We screw the nut welded to the short bolt onto the long bolt until it is between the two drilled holes.

How to use the clamp?

Twisting the wire using a clamp occurs as follows:

- The wire is folded in half.

- Then they put it on the pipe with an elastic band.

- The side of the wire with 2 ends is threaded into the resulting loop.

- Then another turn of the wire is made around the pipe, and again the ends are threaded into the loop. This creates a reliable double knot. It is important that the lines do not intersect, but run parallel to each other.

- Now the clamp comes into play. The notch on the short bolt is pressed into the loop, and the ends of the wire are inserted into the holes in the long bolt.

- Rotate the bolt with holes. The wire is evenly tightened.

- When the overlay is well fixed, the ends of the wire are inserted into the loop and cut off, leaving 5 mm.

Purchased clamps

Repair using a clamp clamp is the easiest and fastest method for repairing leaks in plastic and cast iron pipes. It can be implemented without turning off the water supply. 5-10 minutes of time - and the problem is completely solved. Clamps are often used by amateurs to repair pipes themselves. Professionals consider them as a temporary remedy (“first aid” for a leak).

A clamp is a tightening device in the form of a ring. Its tightening is ensured by a special mechanism: a screw, a worm lock or a cotter pin.

This cheap device can be easily found at the market or in a store. All kinds of clamps are sold in plumbing, construction departments, and supermarkets. The average cost is 30–50 rubles.

The disadvantages of purchased clamps are the weakening of the fastening points and the difficulty of dismantling. Over time, the connection loses its tightness and water begins to leak out again. A correctly installed bandage made of rubber and wire is considered more reliable in this regard. In addition, using a clamp, you can twist the wire so that the connection point is smooth.

Types of clamps

To eliminate a leak, you need to choose the right clamp. Its diameter must correspond to the diameter of the pipe. In addition, the structure must contain a rubber seal.

You can cut the elastic band for the clamp yourself.

There are several types of clamps:

Worm clamp (with and without key). The most common type. It is a tape with a worm screw in the housing. The screw sets the belt in motion and thus tightens or expands the ring.

Metal band clamp. Consists of a long ribbon and clips. You can use it to make clamps for pipes of any thickness.

Double-sided screw. It consists of two semicircular metal brackets that are tightened with screws on the sides. Withstands medium loads.

Wire. Designed for use in conditions of high vibration (in sewer systems, pump hoses).

Power hinge clamp. The fastening is in the form of a ring, the ends of which contain loops with pins. Able to withstand heavy loads.

Clamps with fixed dimensions: ear, spring, latch clamp.

When choosing a clamp, you should pay attention to the thickness and type of metal (stainless steel, galvanized steel) and the quality of the fasteners. They account for up to 60% of the load.

Before installation, the purchased clamp is untwisted and then tightened onto the pipe with a screwdriver or wrench.Typically, twisting is continued until the water stops dripping. But if the pipes are old, they leave a small leak. Within 24 hours, the rubber takes the desired position and seals the hole.

It is important to understand that a bandage and clamp are a temporary solution to the problem. There is no guarantee that the design will eliminate leaks for a long time. Although there are cases where the bandage lasted for 7 years, at the end of the heating season it is still better to replace the damaged section of the pipe.

Questions and answers

What mistakes should be avoided when applying a bandage (collar)?

The most common mistake is to apply rubber pads that are too narrow. The damage may have a large area on the inside. Then the pipe will soon leak again.

The second mistake is cleaning the area being repaired. This is difficult for a non-specialist to do. There are great risks of rupturing the fistulas and getting a real flood.

Is there an alternative to bandages and clamps?

Yes. Bandages and clamps are mechanical repair methods. There are also welding and chemical methods. The first involves soldering, the second involves restoring the pipe body using special glue, sealant, and cold welding. However, all methods except bandage and clamp require stopping the system.

Leaking pipes are an everyday matter. Sooner or later everyone faces such a problem. If you don’t have clamps at hand, a piece of rubber and wire will save you. Anyone can apply a bandage; you just need to tighten the wire harness well. It is best to use a clamp for these purposes. The device is easy to make (see video). Later it can be used to connect hoses, pipes and pipes.

You need to soak everything around with gasoline first. turn on the gas in the oven. Use an ax to cut through the electrical wire and wait for the cotton to thunder! don't worry about the plumber, everyone will be there!!!!

Inventing a clamp to repair a metal-plastic pipe (does anyone have any left?) - it burns!

There is more written here about the clamp than about eliminating leaks. The first thing you need to do is turn off the water