What is the main difference between pressed and unpressed slate?

Content:

The abundance of asbestos-cement sheet materials in stores allows you to choose the desired size and thickness of the sheet. Many of them, upon visual inspection, seem the same, but differ in the manufacturing method, which determines such characteristics as strength and moisture resistance. When choosing a material for construction, you need to know which slate is better, pressed or unpressed, where it can be used and how to properly fix it to the surface.

What is pressed slate

The sheet is made from a mixture of cement 80-85%, water and asbestos 10-15%, which acts as reinforcement, which gives the material sufficient rigidity and strength. High performance characteristics of slate are ensured by the number of asbestos fibers, the uniformity of their distribution in the mixture, the brand of cement and the quality of molding on the production line. Due to pressing, the sheet becomes denser, which invariably affects the strength of the finished product or coatings made from it.

The material is manufactured in accordance with GOST 18124-2012 and has the designation LP-P-3.0x1.5x8, where the last numbers indicate the dimensions and thickness, and the first letters “L” and “P” mean pressed sheet. Most manufacturers adhere to one technology for the production of slate, which guarantees a certain elasticity, strength and moisture resistance, which ensures a long service life of the slate.

Scope of material use:

- Roof covering. Manufacturers paint sheets in different colors, which allows you to create a roof in the same design as the facade. The material is less noisy than metal, cheaper, quite durable and resistant to corrosive changes during operation.

- Installation of formwork when pouring the foundation of buildings. In this case, the material can not be removed after the concrete has dried, which provides additional protection to the surfaces from the effects of negative factors.

- External cladding. Suitable for both wall cladding and for protecting the insulation of basement floors and foundations from the influence of humidity.

- Wind protection of buildings. Flat sheets are often used to line balconies and protect structures made of porous materials from freezing and drafts.

- Construction of small architectural forms. Minimal thermal conductivity makes it possible to construct walls of country houses, outbuildings or pavilions from slate sheets.

- Fencing beds. Manufacturers specially make sheets with dimensions of 1.5-2.0 m in length and 0.3-0.5 m in width to make life easier for gardeners. A high bed made of slate warms up faster in the sun, which affects the speed of harvesting.The sheet does not corrode when in contact with soil or water, does not allow weed roots to grow inside the structure and can last up to 20 years without replacement.

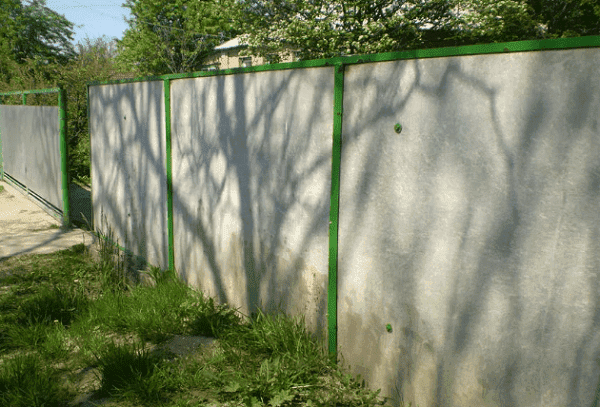

- Installation of fences. The material is relatively easy to install, which allows you to quickly erect a fence of any height and length on the site.

- Indoor floor leveling. Using a sheet, you can create a base for any coating that requires a perfectly flat surface.

The pressed sheet has sufficient moisture resistance and is not susceptible to the formation of mold and mildew, which allows it to be used for external finishing of surfaces and roofs. It is also often used for arranging internal partitions in rooms with an aggressive environment and high humidity.

What is unpressed slate

A material that has not been subjected to additional mechanical stress and after manufacturing only undergoes a drying process. It has the same characteristics as pressed slate, but with lower strength and moisture resistance. The sheets are manufactured in accordance with GOST 18124-2012 and are marked with the designation “LP-NP”.

Recommended areas of application for unpressed slate:

- Interior finishing of surfaces when leveling walls and covering insulating material.

- Dry floor screed and arrangement of a flat surface for decorative finishing.

- Creation of architectural forms of different directions, for example, in the form of a multi-level ceiling or a frame of built-in structures.

The material is easy to cut and process edges, which allows you to make almost any architectural shape with complex elements from it. Slate is more resistant to mechanical damage and moisture compared to plasterboard.

It is acceptable to use unpressed material outdoors, but the service life of such coating will be significantly reduced.

Pros and cons of flat slate sheets

Like any building material, asbestos-cement sheets have a number of advantages, but there are also disadvantages that need to be known and taken into account when considering them as surface cladding or roofing.

Pros of flat slate:

- Low cost compared to other sheet materials. This is due to the simple production process and the low price of the main components in the composition.

- Long service life. Roofs or exterior walls covered with flat slate can last up to 50 years.

- It has a wide thickness range of 6-30 mm, which allows you to select the material based on your strength needs. The length is from 2.0 to 3.6 m and the leaf width is from 1.2 to 1.5 m.

- It is possible to buy the material in different colors and paint it, if necessary, with simple and inexpensive compounds that are used on concrete.

- Easy to cut and does not require special tools. Asbestos cement sheet can be cut to size using a regular hand saw. At the same time, it does not crumble or deform.

- Fire resistance and heat resistance. The material is not susceptible to ignition in a fire, but with prolonged interaction with an open fire it begins to crumble and “shoot” fragments.

- Has excellent dielectric properties. Does not conduct electric current through the canvas during a short circuit or when lightning strikes the roof.

- Resistant to moisture and prevents mold and fungi from spreading on surfaces.

- Has excellent resistance to temperature changes.It tolerates both bright sun in summer and severe frosts in winter. Not subject to structural damage under ultraviolet rays.

Thanks to all these advantages, slate sheets have been manufactured and are very popular among builders for more than 100 years. Non-standard sizes and thickness, which can reach 40 mm, are often used in the construction of industrial facilities when constructing walls. The low thermal conductivity of the material makes buildings warm and durable.

Disadvantages of flat slate:

- Considerable weight. A standard unpressed sheet measuring 3.0x1.5 m and 20 mm thick reaches 190 kg, pressed 100 kg, which makes working alone impossible. To lift such a weight onto the roof, you will have to use winches and several workers.

- Unsafe when cutting. Asbestos, when inhaled, can cause irritation of mucous membranes, so when working with the material you must use safety glasses and a respirator.

- Fragility due to mechanical damage. The sheet can easily support the weight of an adult, but if dropped from a height, it will crack, so you need to be careful when working.

- When used on exterior finishes, additional processing is required. A roof that is not coated with waterproofing compounds can quickly become overgrown with moss, which often happens on roofs made of asbestos sheets.

Flat slate has significantly fewer disadvantages than advantages, which is why it is often used on construction sites as an auxiliary or main material. The main thing you need to know when considering sheets for construction is its technical parameters, which directly affect the service life of the structure.Non-pressed material is significantly inferior to pressed material in terms of durability, especially for roofing and exterior decoration of buildings.

Features and technical parameters of the material

All the characteristics of sheet slate and, accordingly, its cost depend on the production technology. The price can vary from 300 to 1 thousand rubles per unit. When purchasing, first of all, you need to consider the operating conditions of the material and the load on the surface. The boards are hygroscopic and breathable, therefore they are often used in the construction of private sector houses and industrial buildings.

Technical characteristics of slate sheets:

- high bending strength in the range of 18-23 MPa;

- density 1600-1800 kg/m3;

- impact resistance 2.0-2.5 kJ/m2;

- temperature range of use -60+50 degrees;

- number of frost resistance cycles 25-50.

When using the material in difficult weather conditions, it is also worth considering the residual strength after cyclic freezing and thawing, which, regardless of the type of sheet, is about 90%. From which we can conclude that asbestos slate is practically not subject to destruction throughout the entire period of operation and can last much longer than stated by the manufacturer.

What is the difference between pressed and unpressed slate?

The pressed sheet has a significant difference in strength, moisture resistance and frost resistance, so the material, which has undergone additional molding in production, is more expensive and is often used for external cladding of walls and basements.Both types of slate can be gray or painted in different colors to be used not only for protective but also for decorative purposes.

Pressed sheets have better geometry because they have been molded; unpressed material, under incorrect drying conditions, may have obvious defects that cannot be corrected. Therefore, when buying slate in a store, you should carefully inspect each panel for chips and deformations.

Comparison table of two types of flat slate

| Material Parameter | Pressed | Unpressed |

| price | from 250 rub./sheet | from 750 rub./sheet |

| strength | 23 MPa | 18 MPa |

| density | 1800 kg/m3 | 1600 kg/m3 |

| frost resistance | 50 cycles | 25 cycles |

| possible exploitation | no limits | indoors |

What is better to choose, given the difference between materials

Selecting the right material will not be difficult if you know what load it will be subjected to. Particularly popular among builders are unpressed 6 mm panels, which are used to create partitions and decorative elements of walls and ceilings indoors. As well as pressed sheets of 8 and 10 mm, this type of material is often used for roofing and installation of fences in summer cottages and in the private sector. When choosing the appropriate material thickness, it is worth remembering that the higher the indicator, the greater the load the cladding will bear on the structure.

When arranging the roof, it is necessary to make a competent calculation of the truss structure with a maximum margin of safety, which will take into account not only the weight of the covering material, but also the snow load in winter. Often 8 mm thick painted sheets are chosen for roofing.For installation, use a continuous sheathing with a minimum height difference, otherwise large gaps will form between the sheets, which will lead to leaks. The gaps between the slates must be treated with moisture-resistant mastic.

You can use material with a minimum thickness on the fence, while the posts are installed along the length or width of the sheet, depending on the desired height of the fence.

For wall cladding, it is enough to use sheets 6 mm thick, but if we are talking about external covering of surfaces, it is better to choose pressed sheets, which are less hygroscopic and more resistant to mechanical damage.

To carry out work indoors, you can save money and buy unpressed slate, the difference between which is small between the pressed material. Sheets without industrial molding have lower strength and density, but these technical indicators will be sufficient for finishing.

Features of installation of flat slate sheets

The ease of use of the material will not cause difficulties even for a novice master. The sheet can be easily cut with a grinder for large volumes of construction or with a regular hacksaw if repair work needs to be carried out. To minimize dust when cutting, you can moisten the material with water, but the use of personal protective equipment when working is mandatory.

To extend the service life of slate, when using it outdoors, experts recommend treating the cut areas with acrylic paint, which secures the edge and prevents it from delaminating during use.

To fix the sheets to the structure, self-tapping screws or special slate nails are used.If roofing work is being carried out, then the hardware must have silicone or rubber sealing washers, which reduce the impact load on the material when driving and eliminate leaks at the joints.

When installing each fastener, a hole is drilled in the sheet, slightly smaller in diameter than the nail, which will prevent the slate from splitting, the formation of cracks when hitting the head and will keep the structure of the material intact. Using a drill during installation to drill holes can extend the life of the sheet by ten years.

Slate installation can be done end-to-end or overlapping, which is often used when arranging the roofs of private sector houses, when a solid sheet is cut into equal squares. The composite elements are used to create a roof covering that resembles tiles, but when performing such work, it is recommended to carefully process all cuts and seal the junctions of the sheets with mastic.

If construction or landscaping is planned on the site of a private house or country house, then flat slate can be an excellent material for any work. The sheets are affordable, easy to install and durable. The resistance of cement and asbestos to moisture and corrosion has been used in the construction of buildings for quite a long time, and slate does not lose its popularity even with a wide range of new materials.