How to correctly calculate the consumption of polyurethane foam using a calculator and formulas

Content:

When determining the consumption of polyurethane foam, you need to take into account the quality of the foam itself. Weather conditions also play an important role. Let's look at what to pay attention to when making calculations.

Foam consumption factors

To calculate the consumption of mounting foam per 1 meter of seam, you need to study the factors that influence this indicator:

- Accuracy of measurements. The presence of errors in the calculations performed is unacceptable, as this will affect the final result. It is also not recommended to take approximate numbers. It is imperative to use special construction equipment - a tape measure, a rangefinder.

- In addition to general data, the surface itself is also taken into account, namely the presence of defects. Very often, when making calculations, the type of surface is not taken into account, which is a big mistake. For example, if the surface is flat, then exactly as much material will be taken as was calculated. But if there are irregularities, it is necessary to add some reserve.

- Depending on the type of surface, the consumption of polyurethane foam may increase. For example, if a brick wall is 1-1.1 times, a profiled sheet is 1.1-1.6 times.

- Some surfaces are absorbent and will require more foam. Craftsmen are especially advised to take this point into account if they have to work with aerated concrete.

- It is also worth considering the location of the work. For example, if the surface is the same and made of the same material, but one is indoors and the other is outdoors, the consumption of polyurethane foam will be different. Therefore, in street conditions the coefficient increases by approximately 1.2.

- Temperature also has a significant impact. For example, if the outside temperature is -10 degrees, then 1.5 times more polyurethane foam will be needed.

- You also need to increase the raw material by 1.1 times if you have to foam hard-to-reach areas.

- The manufacturer always indicates the material consumption. However, one must take into account the fact that these parameters can only be achieved when working under ideal conditions. Since this can be extremely difficult to achieve, you need to make a certain amount of foam right away.

Attention! If you are going to use some material for the first time, it is best to immediately check it for absorption.

Depending on model

There are a large variety of working units on the market for goods and services, all of which can be divided into several categories:

- Ordinary. In this case, the kit includes a bottle and a plastic adapter for applying the composition. A distinctive feature is the high rate of secondary expansion, which can reach up to 200%. Whether this is a plus or a minus depends entirely on the nature of the work being carried out. The increase in foam volume will be stable and equal.

- Professional. Such cylinders are only suitable for special pistols. The secondary expansion volume is much smaller.However, the stability when increasing in size is greater, which allows you to most accurately calculate the required amount of polyurethane foam.

Polyurethane foam, which increases in size, comes in two stages: primary - after application, secondary - after hardening. Depending on the additives included in the composition, foaming will also differ.

Depending on the conditions of use

Weather conditions affect the yield of the composition. This is explained by the fact that a number of components included in the composition are quite sensitive to operating conditions, which can negatively affect operation. Thus, the following indicators are of particular importance:

- Temperature regime. It is not recommended to use supercooled polyurethane foam, as the properties are lost, the polymerization process becomes worse, and therefore the foaming is unstable, which affects expansion.

- Base temperature. If the surface on which the product will be applied is good enough, then the quality of adhesion is not worth talking about. The foam may roll down or peel off.

- Low humidity. Polymerization catalysts are contained in the polyurethane foam, but the start of the process is affected by humidity; if it is insufficient, the output volume is significantly reduced, as is the expansion of the material.

Advice! Before use, it is recommended to shake the container for 1-1.5 minutes.

Consumption standards

The estimate will depend on how correctly the calculations are made, especially if a lot of work is planned. Depending on the selected composition, indicators may vary.

To make calculations, you need to know the main indicators:

- Output volume is indicated in liters.

- The filling capacity of the seam is indicated in linear meters, taking into account the depth and width.

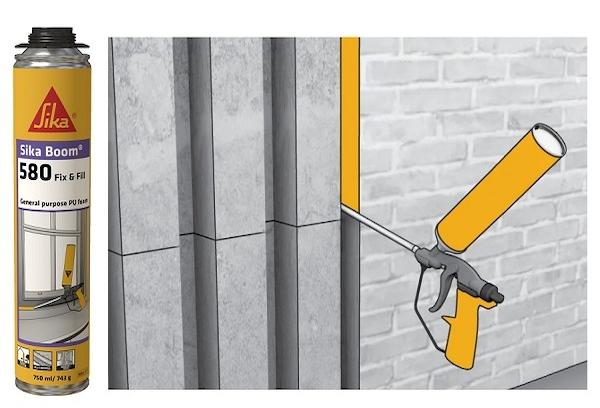

For example, let's take Sika Boom®-580 Fix & Fill foam. Its output is 42 liters; one cylinder can fill 33 linear meters measuring 20*50 mm. Knowing this data, further calculations can be carried out.

Foam consumption per 1 meter: table

If necessary, you can see in the table exactly what the consumption of polyurethane foam will be for 1 square meter of seam. For clarity, let’s take Makroflex polyurethane foam, the volume of the cylinder is 750 ml.

| Seam depth (mm) | Seam width (mm) | |||||

| 6 | 8 | 10 | 12 | 15 | 25 | |

| 6 | 8,3 | 6,2 | 5 | 4,2 | – | – |

| 8 | – | 4,7 | 3,7 | 3,1 | 2,5 | – |

| 10 | – | – | 3,0 | 2,5 | 2,0 | 1,5 |

| 12 | – | – | – | 2,1 | 1,7 | 1,3 |

| 15 | – | – | – | – | 1,3 | 1,0 |

| 20 | – | – | – | – | – | 0,76 |

In the table below, two main parameters are taken into account - depth and width. For example, if the seam has a depth of 6 mm and a width of 6 mm, then one 750 ml Macroflex cylinder will be enough for 8.3 m.p. Thus, the larger these dimensions are, the more polyurethane foam will be required.

Attention! The data in the table is given for operation in optimal climatic conditions; if there are deviations, the consumption increases.

Calculation formula

The formula intended for calculating the consumption of polyurethane foam includes data on the size and configuration of the seams. If the seam is rectangular, apply the following formula:

R=W*D

P – foam consumption (ml/1m.p).

W – seam width (in mm).

Г – seam depth (in mm).

For example, let's take a seam whose depth and width will be identical and equal to 10 mm. In this case, 1 m of seam will require 100 ml of foam.

However, the seams can also be triangular, then the following formula applies:

P=0.5*W*D

Advice! To fill a triangular seam, it is recommended to cut the tip at a 45 degree angle.

Online calculator

To obtain more accurate data, you can use a special calculator, thanks to which you can not only see the material consumption in meters, but also how many cylinders may be needed to carry out the entire work.

When using such a calculator, it is worth taking into account that the data obtained is purely informational. Therefore, it would be useful to add some smell.

Advice! To use the calculator and find out how long the cylinder will last, you need to know some information - foam yield in liters, width and depth of the seam.

Recommendations for economical consumption

When carrying out construction work, it is important not only to correctly calculate the required amount of building material, but also to have an idea of how you can save money.

In the case of polyurethane foam, you can use the following tips to save money:

- It is recommended to leave the foam at rest until complete polymerization.

- To apply the composition, use only professional tools, and not improvised means.

- Before starting work, it is recommended to check the cylinder for serviceability and fullness.

- Purchase polyurethane foam from trusted manufacturers.

- After the composition is applied, it should not be exposed to ultraviolet radiation. As protection, they resort to coloring.

- During operation, you should strictly follow the instructions indicated by the manufacturer on the cylinder.

How to stabilize the foam output (increase or decrease)

During construction work, specialists resort to some tricks, thanks to which it is possible to stabilize certain parameters, for example, in the secondary or primary expansion of polyurethane foam.

Which in turn allows you to achieve better results and make the most of the composition:

- Best before date. Any material tends to deteriorate, including polyurethane foam. Since the shelf life is always standard and is 12-15 months, it is better to use foam that is no more than 7 months old.

- Proper preparation. As mentioned above, you should not work with a supercooled cylinder and apply foam to a cold surface.

- If the humidity level is low indoors or outdoors, then the surface is treated with water, which will increase adhesion.

- It is important to prepare the surface. It is necessary not only to moisten the surface, but also to remove existing contaminants from it; there should be no flaking elements.

Thanks to these rules, you can improve the level of work performed.

Finally

Each selected composition differs in the degree of expansion, which has a significant impact on expansion. You can find out your exact consumption by using special calculators. In addition, many masters, due to their extensive experience, can know for sure how much product will be used depending on the conditions of use.