Lubricate the sewing machine with your own hands

Creaking, thread breaks and other troubles are familiar to every seamstress. Problems in operation are not a reason to take the device to the workshop. Perhaps simply lubricating the sewing machine is enough. Models Janome, Gull, Astralux, Brother, Family and others are processed according to similar rules; find out the details in the instructions for your device.

It's time to oil your sewing machine.

The care work is described using the example of a machine model Janome. Since the internal structure of other varieties differs slightly, these tips and advice are suitable for any device: Brother, Pfaff, Astralux, Husqvarna, Singer and etc.

How to understand that the machine needs attention and needs to be cleaned:

- It creaks or knocks when working.

- Doesn't work with certain thread types.

- The thread breaks.

- The stitches are uneven, the machine skips stitches, and loops appear.

Before work, familiarize yourself with the mechanisms that need to be lubricated, and also pay attention to the correct choice of oil.

What kind of oil to lubricate parts

Use only special sewing machine oil. It is usually included with the tools in a small container. The substance is a silicone lubricant and is characterized by transparency, medium viscosity, and oxidation resistance.

If you don’t find oil in the kit, look for it at a hardware store (ask for universal household oil or special sewing oil).

Important

Car engine oil is not recommended: it is dangerous for car parts! The same goes for vegetable oil. Their characteristics do not meet the requirements.

Where to lubricate: instructions

Before work, remove all threads and remove the needle to avoid injury. Don't forget to unplug the device. For lubrication you will need a small piece of soft cloth (without lint) and a dust brush. If these tools were not included, use a toothbrush and a piece of cotton cloth.

Procedure:

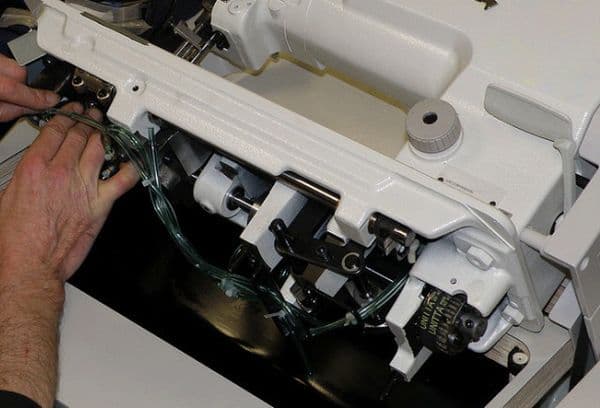

- Remove the panel under which the sewing machine mechanism is hidden. Try not to confuse the bolts, arrange them in the right order.

- Remove dust and debris from the threads using a lint-free cloth or a stiff-bristled brush. All parts need to be cleaned.

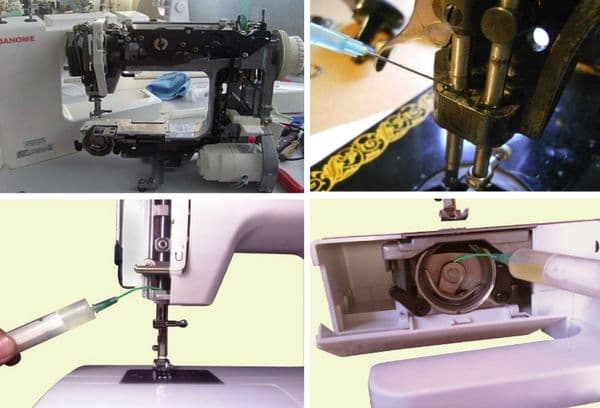

- Next, lubricate all moving metal parts. Find the rod that moves while the machine is running. Apply a couple of drops of oil - for convenience, use a small pharmacy syringe. Its needle will allow you to accurately dose the lubricant. To ensure that the substance is evenly distributed throughout the mechanism, slowly rotate the flywheel. In some machines, places for a drop of oil are indicated by a round hole.

- All that remains is to clean the shuttle compartment and lubricate the roller to stabilize the movements of the mechanism.

purity-en.htgetrid.com magazine recommends measuring the amount of oil for lubrication. More doesn't mean better. Always remove excess with a clean cloth. If you overfill the oil, it will eventually mix with dust, fibers of fabrics and threads, and turn into dirt that is difficult to wash off.

Look for the lubrication diagram in the machine manual. Device designs Podolsk, Juki, Toyota, Jaguar, Veritas may have certain characteristics.If the instructions are lost, then don’t worry: everything that needs care is intuitively clear. As a last resort, call a professional.

How often to clean and lubricate

The frequency of procedures depends on how regularly the machine is used. On average, one cleaning and lubrication per month is sufficient. If sewing is a rare event, then the oil will last for 3-4 months. An old car will have to be lubricated more often.

After lubrication, assemble the device and sew several blank seams so that all parts are evenly lubricated and possible drips remain on unnecessary material. If you are satisfied with the result, then start sewing.