The forester suggested how to sharpen a chainsaw chain yourself with a grinder. Saw beast in 10 minutes

Has it ever happened to you: you planned a bunch of work for the weekend, you just started, and on you: the chainsaw doesn’t cut the tree, but chews it? In such cases, I sharpen the chainsaw chain with a grinder. A forester friend suggested this method to me several years ago. There are no workshops in the forest, but you have to work - in such conditions you can’t do without people’s ingenuity.

The chainsaw method is simple, fast and safe - if you work wisely.

Technical educational program

First, I’ll tell you how a chainsaw chain works. This is important information, without it you will not understand the sharpening technique.

People who picked up the tool for the first time are sure that the wood is sawed by protruding “peaks” - they are even shaped like shark teeth. Actually this is not true. The “peaks” are just the driving links, they are located on the reverse side of the chain.

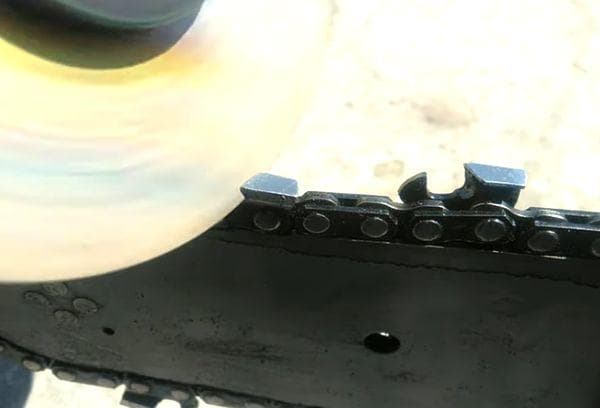

All the work is done by rectangular “brackets” with a curved cutting edge. These are cutting teeth. They are right and left - that is, bent to the right or left.

Now be careful.

There are two types of cutting teeth:

- Chippers. The profile of the cutter is slightly rounded and from the side looks a bit like the top of the number 2. This is the most common option. It is easy to sharpen such teeth, but they also become dull very quickly.

- Chisels. The profile of the cutting edge of the tooth is sharp and resembles the number 7. Chisels are more effective than chippers in their work: they make deeper cuts and dull more slowly. But sharpening such teeth is a five-point task.You need very direct hands and experience.

Before I got the hang of it, I ruined a couple of chains. The problem is that chisels have a very precise cutting edge geometry - it only takes a couple of clumsy movements to ruin it.

My friendly advice to you: if you have a chainsaw with chisels, practice on something simpler first. Don't risk an expensive tool.

Sharpening a chainsaw with a grinder is very easy

First, there is no need to remove the chain. I don’t like to bother with assembling and disassembling the tool.

Secondly, the sharpening angle is determined “by eye”. This is a great time saver.

I often hear from inexperienced craftsmen:

“The grinder ruins the chain, I only use a file!”

And here's what I want to answer:

It is not the grinder that spoils the chain, but the master’s mistakes! I've been sharpening my chainsaw this way for three years, and it works great.

For work I use a small grinder; a 115 mm metal disc is enough for my eyes. We're not going to cut the rail.

I'll tell you about one trick

The metal sharpening disc is harsh, so I always dull it a little before work. I take a very ordinary stone, turn on the tool and “saw through” the cobblestone with a disk a couple of times. Just a little bit, but it's enough to dull the edge a little.

The forester taught me this trick. At first I thought this was some kind of stupidity: why ruin an excellent new disc? But then I tried it and realized: working with a dull tool is much more convenient, and the risk of damaging the chain is reduced. Now I always use this “secret technique” - and I advise you.

Important Procedure

To properly sharpen a chainsaw chain, I do this:

- Before work, I place the chainsaw on the table and clamp the bar with a vice to prevent it from jerking. This is a very important point. The chain must be stationary.If it slips, you will completely ruin the geometry of the teeth.

- I set the grinder to low speed. I have a semi-professional tool, it has the necessary function. On simpler angle grinders, the number of revolutions depends on how hard you press “Start”. Therefore, press the start button softly.

- I will direct the disc at an angle to the plane of the tooth - approximately 30° and tilt it slightly. The disc should be adjacent to the cutting edge, repeating its geometry. Gently, with soft touches, I press on the tooth - literally “stroking” it with a disk.

- It is very important not to overdo it here. As Carlson used to say: “Calm and only calm.” And also moderation. Overdo it a little and grind the cutting edge clean. Well, or overheat the tooth, and the chain will fall off during operation.

- I move around and work on all the right teeth first. Then I turn around and go to the left - that is, I sharpen my left incisors.

In 10-15 minutes the chain is ready for use.

Another sharpening method

Some craftsmen clamp in a vice not a chainsaw, but a grinder. Well, or they attach it to a workbench - whoever has what.

They work in the same way as on a grinding wheel: turn on the grinder and bring the chain to it with your hands. The angle is kept the same - conventional 30°.

I was highly praised for this method: it’s faster, easier, and my hands get less tired. The chain is lighter than an angle grinder.

But personally, I don’t approve of this sharpening option. The teeth on the tape are small, which means that your fingers are very close to the rotating disk - which, by the way, easily cuts metal. The hand trembles a little - and goodbye, finger.

Is it worth taking such a risk for 5 minutes of saved time?

When the grinder is not at hand

I use a very ordinary round file.I select the diameter of the tool depending on the pitch between the cutters.

There is nothing complicated about this: just apply files to the teeth and see which one fits comfortably into the opening.

I’ll warn you right away: this kind of sharpening will take a lot of time, and you’ll pump up your arms like Schwarzenegger. But you can work in any conditions: even in the country, even in the forest.

The principle of operation is as simple as boots:

- Take the saw and place it in a comfortable position. Someone secures the tool on the workbench, but I just clamp it with my knees.

- We apply the file to the tooth at an angle of 30°. Nothing changes here.

- Sharpening. Whack-whack, everyone can do it.

- We move from tooth to tooth, maintaining the same cutting edge angle.

Work not with the middle, but with the upper ring of the file. The tip on the opposite side of the blade should protrude approximately 1/5 of the length.

We move the file carefully, do not pull or press. You are not grinding off burrs on the metal, but forming a cutting edge.

And no turning back! This way you will ruin all your work: you will dull the blade that you just sharpened.

Do not forget to rotate the file so as not to sand the same section of the work surface.

Chisels cannot be sharpened this way. You will not be able to maintain a straight cutting edge because the file has a round tip. And a rounded chisel is a damaged chain that can only be taken to a landfill.

Exotic with drill

I recently learned that a chainsaw can be sharpened with a drill. I honestly admit: I was very surprised. Only our Russian left-hander can think of such a thing.

How it works:

Instead of a drill, they put... a file on the drill. Yes, yes, the same one you just read about.

Preparing for work is a full-fledged quest.

- First, the shank of the file is cut off.

- Then they select a bearing “by hand” - one that is convenient to hold by the outer race.

- A bushing is cut out of wood or cork to fit the dimensions of the bearing. The contact must be tight.

- Insert the bushing into the bearing and secure the file in it.

Well, then the fun begins.

- The saw is clamped in a vice so that the blade remains motionless.

- The chain is loosened so that it can wind freely.

- The file is inserted into the rounding of the tooth, maintaining the correct sharpening angle - the same standard 10-30°.

- The master holds the drill with one hand - the way they usually hold a tool when working. And the second he should take hold of the bearing. More precisely, for its outer casing.

After pressing the “Start” button, the file begins to rotate, sharpening the tooth. But the drill is not suitable for such work, and the file vibrates during operation, so you need to hold the tool tightly. And even in this case, there is no guarantee that you will not grind down the cutting edge so that it cannot be restored.

You need to work very carefully. The master literally “touches” the tooth and immediately turns off the tool.

I tried this method a couple of times and didn't like it. Labor-intensive and complex work without a guaranteed result. But I personally know a master who sharpens chainsaws this way and is very pleased with the result.

The file can be replaced... And the drill too

If you are not a fan of extreme sports - and I, for example, am not - use a screwdriver instead of a drill. The dimensions are smaller, the power is lower, and it is more comfortable to hold in the hand.

And instead of a file, order a diamond tip about 5 mm thick from Aliexpress. These sizes fit most chainsaws.

We work in the same way as with a file:

- We insert the tip into the socket, lightly press it against the tooth and sharpen the edge.

- Turn on the screwdriver for 2-3 seconds. We move the tip back and forth, but only slightly, half a centimeter maximum.

In about 15 minutes, it is absolutely possible to adjust the saw to working condition.

In traveling conditions, the method is convenient: the screwdriver does not take up space in the trunk, weighs little, and does not need to be connected to the network.

But you will have to spend money on tips. In addition, consumables spoil quickly, so I order 5-10 pieces at once. I’ll find it useful myself, and I can share it with the men if they ask.

What to do to prevent the saw from becoming dull

The less you dull the saw, the less often you will have to sharpen it. Observing the tool, I came to the conclusion that the following works kill the chain the most:

- Sawing raw or resinous wood. Wet pine logs are murder on a cutting edge.

- Working with rotten wood. The material seems to be soft, but the teeth get stuck in it, and the edge becomes cramped.

- Sawing hard wood. Do you work with oak, cherry, acacia, elm, or walnut? Get your grinder ready, you'll need it.

Another problem is the mistakes of the craftsmen.

When I first learned to work with a chainsaw, I put a lot of pressure on it. The result is permanently dull cutting edges.

I also didn't adjust the tension. The chain either dangled or sagged. Such a mistake also dulls the teeth.

Well, the last problem that any man who has ever drank horizontal logs has encountered. Earth! Did you miscalculate the force and hit the ground with your saw? That's it, we've arrived. Earth and sand dull teeth very quickly. A few of these mistakes and the saw will have to be sharpened.

Take care of the instrument, care for it properly - and everything will be fine!