We made noise insulation for pipes: this is a solution if you are also tired of hearing sound from neighboring apartments

Soundproofing sewer pipes is not an idle whim, but a necessity. We came to this conclusion after moving to a new apartment. I must say that before this we lived either in private houses or in old high-rise buildings, where all communications were laid back in the era of cast iron pipes, so we did not encounter such sound effects.

The regular noise of the “waterfall” in the new building came as a surprise to us - either while lying on the bed in the bedroom, we heard in our sleep how our neighbors were enjoying the benefits of civilization, or while reading a book in the living room, we were startled by a sharp rumble. What can we say about those moments when a sharp roar of water hit us while we were in the bathroom. Therefore, we began to look for the reasons for the noise and ways to get rid of it.

Causes of noise in pipes

After talking with several plumbers, it turned out that the noise of water in the pipe arises precisely because of the low sound insulation properties of the material from which this very pipe is made. Plastic, unlike cast iron, absorbs vibrations very poorly. It is also smooth, so grease and other waste does not stick to it. On the one hand, this is good, since the likelihood of blockage is reduced. But on the other hand, the layer of sewage serves as an additional “dampener” of noise.

However, these are not the only reasons for the appearance of extraneous sound in the apartment:

- The seal plays an important role. Experts advise using rubber gaskets and polyethylene foam. In our case, the builders decided to save money and blew everything out with ordinary polyurethane foam, which conducts sound perfectly.

- Sewerage is not a hermetically sealed system. Due to the nature of its design, wind can enter the pipes. The result of the movement of dense masses of air in a tight space is noise.

- If we consider sewer pipes from the point of view of physics, then they are nothing more than a resonating device. In turn, a house is a “living organism”. It is not static - the ceilings compress and expand under the influence of air temperature; Processes also constantly occur in the soil, which lead to the fact that the foundation and walls constantly vibrate. Such vibrations are imperceptible to us, but, transmitted to the pipes and amplified many times over, they turn into a clearly distinguishable hum.

There are also more serious causes of noise - for example, improper installation of sewer systems. According to the rules, they must be located in interfloor ceilings. If the installation is carried out with violations - that is, the pipes are located in the inter-apartment walls and interior ceilings, the audibility of sounds increases many times over.

Soundproofing of sewer pipes

One of the plumbers with whom we consulted about sound insulation offered us an alternative option - replacing the pipes with others with thicker walls. They are made from a special mixture of plastic and minerals, so the sound in them fades faster. However, having calculated how much money such an idea could cost us, we abandoned it.Moreover, the decisive factor was not only money, but also faster wear and tear of the system - if conventional PVC pipes last for half a century or even more, then improved ones will have to be replaced after 20 years.

As a result, we came to the conclusion that in order to reduce the noise level and not go beyond the budget, it is necessary to cover the risers first with vibration-isolating material, and then with noise. At least, all the people we interviewed on the forums advised this particular option as the most profitable.

Next, we started directly selecting materials. Our criteria were:

- the presence of a self-adhesive layer - so as not to bother with the selection of glue and its application;

- reasonable cost;

- quality - nevertheless, we were counting on, if not the complete disappearance of noise, then at least a noticeable reduction in its volume.

In the end, we settled on StP Aero Plus, 3 mm thick, as vibration isolation, and bought 6 mm flex to protect against sound.

Taping risers in the toilet and kitchen

Saving means saving. In order not to spend money on the services of builders or plumbers, my wife and I decided to glue the insulation in the toilet and kitchen with our own hands. Moreover, this process is not complicated:

- To begin with, we degreased the riser, the fan pipe and all the jumpers from all sides, wiping them with a rag moistened with acetone.

- We measured the pipe coverage.

- Markings were applied to the vibration insulation sheets with a pencil and the material was cut out with a utility knife.

- Using a level, we drew a straight vertical line on the riser. It is needed so that when gluing the material does not “creep” to the side and kinks do not appear.

- Vibration insulation was applied.For convenience, the protective paper was not completely removed from the adhesive layer - first from one edge and immediately fixed it on the pipe, and then gradually wrapped the material around the riser, also gradually separating the protection.

- Flex was glued on top of the vibration isolation in the same way.

It should be noted that if Aero Plus gave some freedom of action - in case of an error it could be peeled off and glued back, then with flex we had to work on the principle of “measure seven times, glue once”, since any wrong movement could ruin the whole work.

Sound insulation of heating system

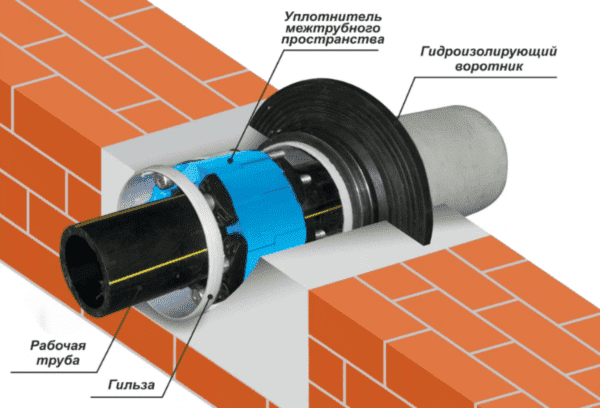

The problem with sewer noise was not the only one. We could also hear all the neighbors' conversations from the lower and upper floors - the sound came through the openings provided for the heating system. The fact is that the riser is not mounted end-to-end with the floor, ceilings and other building elements.

For safety, it is placed in a special metal sleeve, the diameter of which is much larger than the diameter of the pipe. And so that there is no open gap between the apartments, the gap between the pipe and the sleeve is filled with whatever comes to hand, starting from cement chips and ending with ordinary garbage - newspapers, scraps of rags. We knew that they built this way 30-40 years ago, but the fact that in new buildings they use the same method surprised us. Therefore, we decided at the same time to repair the sound insulation where the heating pipes ran.

As consumables, we chose scraps of asbestos cord and a special Vibrosil sealant - it was recommended to us by friends who already had positive experience in using this product.True, it turned out to be not so easy to get it - the story of how much effort we spent to order such a sealant through tenths of hands is worthy of a separate story.

Sealing the space between the sleeve and the heating riser

As with the sewer pipes, we did all the work ourselves.

This task also turned out to be easy:

- First, they removed all the debris that the builders had used instead of insulation.

- Then we thoroughly cleaned and degreased the inside of the sleeve and the surface of the pipe.

- They hammered scraps of asbestos cord into the sleeve, not reaching the top by 4-5 cm.

- They poured Vibrosil over the cord. They did this using a special pistol. It is impossible to squeeze out the sealant by hand - it is so thick and dense.

- We straightened the seam so that it looks aesthetically pleasing.

We acted according to the same principle both when working with those sleeves that are mounted in the floor and with those on the ceiling. After the sealant hardened, the sound disappeared almost completely - only isolated screams and the loud barking of a dog can be heard.

This is how we solved the problem of lack of sound insulation in plastic sewer pipes and got rid of the need to hear all the neighbors’ conversations. The costs were minimal, and the effect was remarkable.