Note for winter fishing lovers: 7 ways to sharpen an ice drill knife at home

Dull ice drill knives have one advantage: fruitless attempts to drill through the ice prevent you from freezing. And jokes aside, every fisherman secretly dreams of learning how to quickly and easily sharpen ice drill knives. Sooner or later they all get stupid. And very often this happens at the most inconvenient moment. There are several ways to solve the problem.

Methods of sharpening “on the knee”

Modern fishermen have ice screws of various modifications in their arsenal. Some are designed for thaws, others for frosts, for loose and hard ice. The main difference is in the design of the blades and the shape of the cutting edge. In addition to the usual flat knives, there are semicircular, spherical, stepped and serrated ones. Depending on the type of knives, a different sharpening method is used.

The easiest way to sharpen ice drill knives at home is Barnaul and Leningradsky.

They are flat, straight, and have two sharp edges. The sharpening process is simple, but long.

Using sandpaper

In the magazine Rybolov No. 1 of 2003, the following sharpening method was described:

- Take 3 strips of sandpaper numbers 2, 1 and 0.

- We start with coarse sandpaper. Press it tightly against the blade.

- We sharpen the knife by moving it from top to bottom.

- When scratches form on the surface, move on to grit sandpaper.

- Bring the blade to a shine with fine sandpaper.

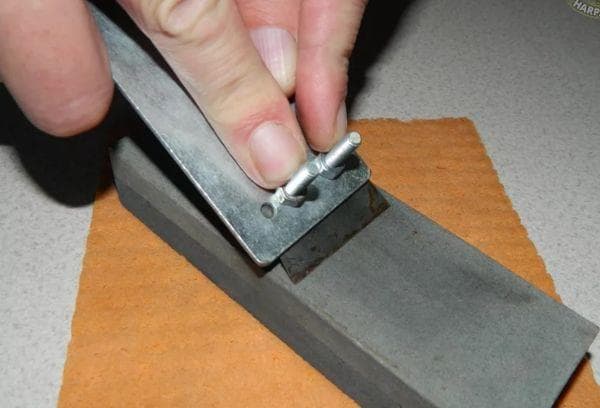

With the help of a touchstone

There is a sharpening stone in every home. With its help you can sharpen not only kitchen knives, but also ice drill knives.The principle is the same:

- The touchstone is fixed on the table.

- The blade is installed on the stone at an angle so that the wide edge fits tightly to the surface.

- The knife is pressed with your fingers and smoothly drawn across the stone towards you. You need to apply light pressure on the blade and make sure that the metal is scraped off evenly from the entire surface.

- Sharpening continues until the tip begins to easily cut a sheet of paper.

You can fix both the whetstone and the knife itself. To do this, you can screw it to the board with screws.

Through the collapse of the edge

The old instructions for the Leningrad ice auger contain interesting information about the edge being blocked. The point is to leave a burr on the back of the blade after sharpening. It is necessary to sharpen with a file towards the cutting edge. The burr will become more pronounced and durable. It is important. It shouldn't break off.

The presence of a correct burr is determined with a fingernail from the back of the knife. The nail should cling to it. It looks like this:

Older fishermen often use a rolled edge. Carry a screwdriver with you. If the fishing drill refuses to work, run a screwdriver along the edge of the blade at an angle slightly greater than the sharpening angle. A fresh burr is formed and the ice auger works like new. The collapse of the edge eliminates the need to remove and sharpen knives. You can use them until serious chips and nicks appear.

Sharpening angle

The main rule for sharpening any tool is to maintain the factory sharpening angle.

Beginners often neglect it. Sharpening the entire plane of the edge takes much longer than simply chamfering the edge. As a result, when chamfering alone, the factory sharpening angle is violated. After just 1-3 procedures, the knife becomes completely unusable.

When sharpening Leningrad Bor knives, a sharpening angle of 30 degrees is usually maintained.

If the angle is made sharper, the drill will bite into the ice better. But it will also become dull at a catastrophic speed. In addition, a thin edge is more fragile. It is easier for nicks to form on it from frozen grains of sand and pebbles.

You can set the desired angle on a cross-cutting machine, which is used to install doors.

Craftsmen often make their own devices for maintaining the angle. A permanent marker is also used for these purposes. They are used to paint the metal that needs to be removed.

Sharpening semicircular knives

Spherical knives drill through both dry and wet ice with equal ease. But not every master can sharpen them correctly. The difficulty is that the blade has a convex appearance. The cutting edge is semicircular, and therefore the movements must be special.

It is necessary to turn the tool in a timely and smooth manner, otherwise the sharpening angle will be completely blocked.

To make their work easier, some fishermen buy special devices for sharpening semicircular knives. But there are also “home” methods.

Using water stone

As a last resort, semicircular knives are also sharpened on a stone. In total, instead of whetstone, it is better to take a 3000 grit water stone.

- Soak the stone in a bucket of water.

- Place it on a table covered with film.

- Press the edge to be sharpened with your fingers.

- We carry out the entire surface.

- You need to repeat the bend and maintain the angle. A permanent marker and constant monitoring will help with this.

A clear example of sharpening knives for an ice drill Tonar Iceberg 130 on a wet stone:

On ice

Well-known Russian method. Many fishermen sharpen even Swedish Mora ice screws on ice. Sharpening (or rather editing) is performed as follows:

- The drill is placed on the ice with knives pointing to the sky.

- Take a good knife with a strong blade (a file, a screwdriver).

- The drill blades are straightened until a magical edge is formed.

- 10 minutes of simple steps, and the drill penetrates the ice like butter.

Advice. In order not to ruin your fishing with a ruined ice screw, you need to beware of ice with grains of sand. It is mainly found in coastal areas. It also doesn’t hurt to take a set of spare knives, a screwdriver or a file for straightening when going on ice.

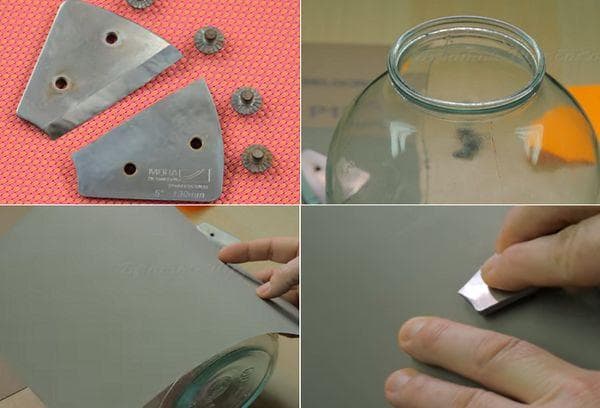

On the bank

Another popular home method. The secret to sharpening spherical knives is to use a glass jar. It helps keep the bend.

How to sharpen knives correctly:

- Take 1500 grit sandpaper (1-3 sheets) and a 3-liter glass jar.

- Place the sandpaper on the side of the can.

- Place a knife on top. Press the blade well with your fingers.

- We sharpen it with sandpaper, moving it back and forth (in small movements).

- When the grain is erased, move on to the next section of paper.

- Continue until small scratches appear across the entire surface.

- Then we sharpen the knife with transverse movements.

It takes 10-15 minutes to sharpen one knife. But then the drill drills perfectly into the ice for at least two winter fishing seasons.

Video of the process (sharpening Mora knives on a can):

Ice drill knife machine

In workshops, ice drill knives are sharpened on professional machines. It is not profitable to buy special machines for yourself. The price for them can reach up to 75 thousand rubles and more. At home, they usually use a standard electric sharpener.

Any knife can be sharpened quickly on the machine – in minutes. But another problem arises: the blade can be damaged just as quickly. A split second is enough for the rotating disk to block the sharpening angle.

Therefore, those who have never worked on a machine need to think carefully. If you decide to use a sharpener, various devices will come to the rescue to help you maintain the desired angle. The simplest option:

- Cut a large triangle and a rectangular strip from plywood.

- Screw the knife to the plywood. Support with a bar, as shown in the photo:

- Place a heavy plate on the table (to support the plywood).

- Color the edge of the knife with a marker. Press the plywood with a knife onto the disc.

- By turning the disk by hand, adjust the stop so that the marker is erased over the entire area of the edge.

- Secure the base plate with clamps.

- Sharpen the blade by smoothly moving the plywood along the support.

Advice. To make the sharpening process more effective, the knife must be cleaned and degreased. This will increase the coefficient of adhesion between steel and the sharpener.

More details in the video:

The second option for sharpening ice drill knives:

Important. When sharpening on a machine, the knife must be cooled regularly (dipped in a bucket of water).

Knife sharpener

Fans of running (search) fishing often choose something between a touchstone and a machine tool - an ice drill knife sharpener. It allows you to adjust the sharpening angle and make precise movements. The risk of error is minimal. A sharpener can be used to sharpen any cutting tool. The device costs about 4,000 rubles.

What sharpening looks like in practice:

Questions and answers

Why does an ice drill drill poorly?

It happens that even a new drill does not bite into the ice, but strokes it on top. This may be due to incorrect installation angles, a crooked line of the mating plane, or insufficient tightening of the bolts. All these factors change the angle of attack to some extent.It is also important to be able to tune the instrument, depending on what kind of ice is on the river now, dry or wet. To do this, pads are inserted under the blades and washers are used.

Do blades need to be polished?

After proper sharpening, scratches and burrs remain on the metal. At first glance, they do not affect anything and do not particularly complicate the drilling process. But experienced fishermen still advise getting rid of them and polishing the surface to a mirror shine. Defects cling to the ice. As a result, the tool wears out faster.

How can you tell if your drill knives are well sharpened?

You need to look at the crumbs that are formed during the drilling of the hole. If it is large, it means that the tool is “tuned”, the blades are sharp and have the correct angle.

Sharpening ice screws is a sore subject for many anglers. Most take the easy way out and buy new sets of knives every time the old ones get dull. After a couple of years, a small warehouse of old kits appears at home, which look like “nothing yet.” Then, willy-nilly, you think about sharpening your knives yourself. Simple flat blades are easy to revive. With a little practice, you can get a working tool with a minimum of cost and effort. Mora and Rapala knives are another matter. Only a few will be able to sharpen and even edit them with their own hands. You will need a sharpener or a good craftsman.