How to correctly measure a window to install a mosquito net?

To make a mosquito screen yourself or order it from a manufacturing company, you need to know the exact dimensions. Usually, in order to measure a mosquito net for a plastic window, a specialist is invited. But in fact, measuring the opening of a window or door to a balcony is not difficult. Let's look at the measuring instructions, find out what tools are needed, and consider all the intricacies of the process.

Is it worth measuring yourself?

Today, the market for services for installing plastic windows and manufacturing components for them is quite saturated with offers (at least in large and medium-sized cities). In many cases, it is more profitable not to bother with measurements yourself, but to invite a specialist. However, there are several situations where this solution may not be the most beneficial:

- In small towns, holiday villages, urban settlements and villages, there may simply not be a single representative office of companies engaged in the manufacture of windows and window components. Calling a surveyor in such conditions may require a long wait and payment for the services of a specialist.

- Some people prefer to save on the services of specialists by making the mesh screen themselves. In this case, paying for a surveyor to come out is simply unprofitable. And when ordering mesh from the manufacturer, not calling a measurer will help you save money.

Before contacting a particular company, study the rules of its work and the regulatory documentation presented on the website.Many companies stipulate in their rules that they should not use measurement results made by anyone other than a company specialist.

Many people prefer not to bother with measurements, not being confident in their own ability to measure correctly. But in fact, anyone with minimal skill in working with a tape measure can measure the light opening of a window.

Consequences of measurement errors

Before deciding to carry out all measurements yourself, it is worth considering the consequences of a possible error. They can be divided into three groups:

- The mesh turned out to be larger than necessary. Even a deviation of a few mm can be enough to prevent the mesh from fitting into place. In this case, adjustment can solve the problem, but with its help it will only be possible to correct an error of 1–2 mm.

- The mesh turned out to be smaller than required for the project. In this case, it will fit into place, but will not be attached tightly enough. Small insects can get into the cracks between the mosquito screen frame and the window frame. In addition, there is a risk that the mesh will simply fall out of the fastenings and fall from a great height, becoming unusable.

- The specifics of the window installation do not allow the mesh to be attached to it using the chosen method. This is not a consequence of an error in measurement, but of an error at the stage of determining the type of structure. However, the consequences are approximately the same: due to the discrepancy between the dimensions of the mesh and the requirements of the project, it will not be possible to put it in place.

As a rule, mesh manufacturers stipulate in their customer service rules a waiver of warranty service and replacement of the mesh if the malfunction arose due to an error during self-measurement.

In order to avoid unpleasant surprises, you must do everything to calculate the dimensions of the mosquito screen frame as accurately as possible. Check each measurement several times, record the results carefully, and take your time. Then the measurement quality will be sufficient to solve the problem.

Where to begin?

Before measuring the light opening, you need to decide which mosquito protection mount you want to use. Depending on the type of mesh and the method of its attachment, the dimensions will differ.

Most often, frame meshes are installed on plastic windows.

They are designed simply: it is a piece of cellular canvas (usually made of polymer materials) mounted on a frame made of plastic or aluminum profile. Thanks to its maintainability, durability and low cost, this design confidently holds first place in popularity. There are three ways to attach such a grid to a window:

- Using plunger pins. The plunger is a spring-loaded pin installed in special holes in the window frame. Thanks to the springs, these clamps securely hold the mesh in place and make it easy to remove if necessary. In this case, the mesh frame is inserted strictly into the opening of the window frame.

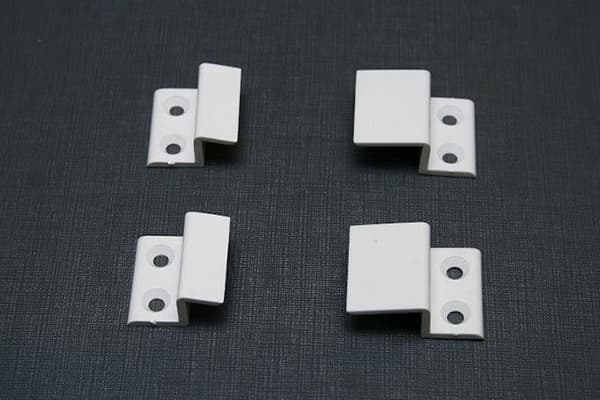

- Using Z-shaped brackets. The frame attached to such hooks will be located on the outside of the window frame. It will be as easy to remove as one secured with a plunger fastening. The main advantage of this option is its ease of manufacture and installation.

- Installation in corner “pockets”. This method was developed first.Similar to z-bracket mounting, the mesh frame is also located on the outer side of the window frame. “Pockets” are easy to make yourself from a metal strip. That’s why homemade structures are so often attached. But this method of fastening has several disadvantages, the main one of which is the lack of tight pressing of the frame to the window frame.

It will be possible to attach a frame mesh to the window only if the window opens into the room.

There are other ways to attach mosquito curtains, for example, pleated curtains, sliding structures on the loggia or swing nets on the balcony door. The measurement technique and rules for determining dimensions for these types of mesh screens also have their own specifics.

Preparing the measuring tool

To obtain the length and width of a window opening, you do not need a high-precision measuring instrument. An ordinary household tape measure with a length of 3 m is enough. This is the main, but not the only tool that should be prepared when planning to take measurements for making a mosquito net.

In addition to the tape measure you will need:

- pencil for making marks on the frame and recording results;

- a sheet of paper on which the draft of the future grid will be drawn up;

- tools for checking the correct installation of frames (plumb line, construction bubble level, squares).

The more accurate the measurements are made, the better. If you rush into rounding, turning 1124 mm into 112 cm, the finished mesh may be too small or too large.

Today, many professional measuring instruments have been invented (laser levels, rangefinders, etc.), which significantly facilitate the work of professional measurers. But they are not required for everyday work.Of course, if possible, you can use them.

Let's take care of safety

Another aspect that needs to be mentioned is ensuring safety when carrying out work on measuring the mesh and installing fasteners for it on the window sash. Some manufacturers do not undertake to install nets on finished frames at all, since this is a labor-intensive and inconvenient process. The installer has to lean out into the opening, and he has practically nothing to hold on to (after all, his hands are full of tools and fasteners). Ideally, all work is carried out before installing frames in window openings.

But most often there is nowhere to go, and you have to carry out work on already installed windows. In this case, it is necessary to take care of a reliable base for support. You should not stand on rickety stools or other improvised supports to reach the top edge of the window. You need to work only on a stable base: stepladder, sawhorses, etc.

Do not start working near an open window if you feel unwell. Reduced coordination of movements (due to taking medications, alcohol, acute or chronic diseases) can cause a fall from a height!

We take measurements and design a mesh for Z-shaped brackets

In this case, the mesh frame will be mounted outside the window. First of all, you need to make sure that this type of installation is possible in principle. To do this, you need to open the sash and measure the width of the free part of the frame on all four sides: top, bottom and sides. This is done to ensure that the window frame does not extend too deep into the quarter and there is enough free space to install the fasteners.

It is especially important how much space is available at the top, since the top Z-brackets are long.If the top of the box extends into the quarter by more than 3.5 cm, it will not be possible to install the Z-shaped brackets. You need at least 2 cm of free space on the sides and bottom, although it is much better if there is 3 cm or more.

There may be other interference that prevents this installation method from being used. For example, window grilles installed too close to the frames, slopes located too close, etc.

If there are no obstacles to installing the mesh on the Z-shaped fastenings, measurements are taken as follows:

- Measure the width of the window's light opening. Add 25–30 mm on each side. For example, the opening width is 600 mm. Then the width of the mesh is calculated as follows: 600 + 2 x 25 mm = 650 mm (or 65 cm).

- Measure the height of the opening. Add 35 mm to the upper part of the resulting segment, and another 25–30 mm to the lower part. So, if the height is 1490 mm, the height of the mesh is calculated as follows: 1490 + 35 +25 = 1550 mm (or 155 cm).

The dimensions of the frame for the mosquito screen are determined in the same way when it is planned to be installed in corner “pockets”.

We take measurements for the mesh secured with plungers

The peculiarity of the plunger fastening is that the mesh is not located on the outside of the frame, but directly in the opening. It will not be possible to use such a mount if the outer protrusion of the frame has a strong bevel (or a rounded bevel). In this case, the plungers simply will not provide reliable fixation of the mesh in place.

Determining the dimensions of the mesh in this case is simple: you need to measure the height and width of the light opening, and then subtract 3 mm from each side. For example, for the opening from the previous example (remember, width – 600 mm, height – 1490 mm) you will need a mesh with the following dimensions:

- width: 600 mm – 6 mm = 594 mm (59.4 cm);

- height: 1490 mm – 6 mm = 1484 mm (148.4 cm).

A frame mosquito screen with these dimensions will be securely fixed with plungers in the window opening. A small gap (3 mm on each side) will reliably cover the pile of the sealing brush.

If you carry out all the operations of measuring the window opening and calculating the dimensions of the mesh carefully, the obtained values will allow you to make a mesh that will ideally fit your window. It's worth the effort, isn't it?